Mechanical nuts, also known as nuts, are fasteners used to secure or connect components, typically paired with bolts or screws. With over 15 years of experience in the fastener industry, I’ve learned how important it is to choose the right type of nut for each project. Different jobs require different types of nuts, and even experienced professionals can sometimes find it challenging to select the best one. To make this process easier, I’ve put together a list of the top 15 most commonly used mechanical nuts, their key properties, and their best applications. This guide will help ensure you pick the right nut for the job, whether you’re working on machinery, construction, or another project.

1. Cap Nuts

Cap nuts, also called crown hex nuts or blind nuts, have a domed top that covers the end of a bolt or screw. This design protects the threads from damage and prevents contact with other objects. Cap nuts also give a cleaner, finished look. They are usually made from materials like brass, steel, stainless steel, or nylon and can be polished or chrome-plated for a shiny appearance. There are two main types: standard cap nuts and high cap nuts, which are taller to cover longer threads. Some versions also have self-locking features to prevent loosening.

2. T-Slot Nuts

T-slot nuts are specially made to fit into T-shaped slots on worktables, machines, and structural frames. They allow for easy positioning and secure fastening without needing to drill holes. These nuts are perfect when you need to move or adjust components. T-slot nuts are usually rectangular or square in shape and come in different thread sizes to fit various bolts. They are typically made from steel, stainless steel, or aluminum to ensure strength and long-lasting use. To prevent rust, many are zinc-plated or treated for corrosion resistance.

There are several types, including standard T-slot nuts for everyday use, heavy-duty T-slot nuts for higher loads, and low-profile versions that sit lower when installed. You’ll often find them in workshops, CNC machines, and industrial setups where things need to be securely fastened but also easy to adjust.

3. Flange Nuts

Flange nuts have a built-in, washer-like base that spreads the pressure evenly across the surface. This helps protect the material being fastened and reduces the need for a separate washer. Flange nuts are commonly made from steel or stainless steel and can be zinc-plated or coated to resist corrosion. Some flange nuts have serrated edges that prevent them from loosening due to vibrations. They are often used in automotive, plumbing, and metalworking projects.

4. Nylon Insert Lock Nuts

Nylon insert lock nuts, or Nyloc nuts, contain a nylon ring inside the nut that grips the threads of a bolt tightly. This extra grip helps prevent the nut from loosening, even when exposed to vibrations. They are ideal for use in applications where vibrations are common, such as in cars or industrial machines. Nylon insert lock nuts are made from carbon steel or stainless steel and are often coated with zinc to protect against rust.

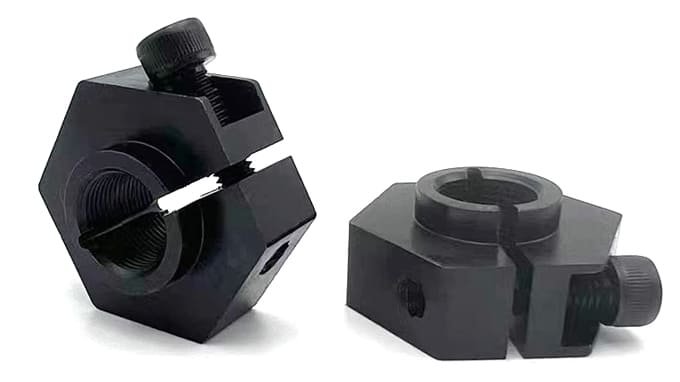

5. Split Nuts

Split nuts are unique because they come in two halves, allowing them to be placed around a threaded rod without having to rotate the nut. This makes them perfect for applications that require quick adjustments. Split nuts are usually made from carbon steel or stainless steel and are used in lathe systems or machinery where positioning is important. They may be coated with zinc to protect against rust.

6. Wing Nuts

Wing nuts are designed for quick and easy tightening by hand, thanks to the large “wings” on either side. They are ideal for situations where you need to make frequent adjustments or disassemble parts quickly without tools. Wing nuts are typically made from aluminum, stainless steel, or plastic. They are used in furniture, lighting, and equipment that requires easy and fast fastening.

7. Knurled Nuts

Knurled nuts have a ridged exterior for better grip, making them easy to tighten by hand. These nuts are commonly used in applications that require frequent adjustments, such as electrical equipment or precision tools. Knurled nuts are typically made from aluminum, stainless steel, or plastic, and can come with a plain or coated finish for added protection.

8. Square Nuts

Square nuts have four sides instead of six. Their larger surface area makes them less likely to loosen, as they provide more grip. Square nuts are typically used with square-headed bolts, often found in older construction or machinery. These nuts are made from materials like carbon steel or stainless steel and can be zinc-plated to resist rust.

9. Coupling Nuts

Coupling nuts, also known as extension nuts, are long and cylindrical with a hexagonal exterior for easy wrenching. They are fully threaded inside and designed to connect two male-threaded parts, like threaded rods, together. Coupling nuts are useful for extending the length of bolts or rods. They are commonly made from carbon steel or stainless steel and are often zinc-plated for rust protection. You’ll find them in construction and machinery where longer connections are needed.

10. Insert Nuts

Insert nuts, or threaded inserts or rivet nut , are cylindrical nuts used to provide strong threads in thin materials, like sheet metal or plastic. These nuts are installed by drilling a hole and then securing the nut with a special tool, creating a durable threaded surface. Insert nuts are typically made from steel, aluminum, or brass, and can be treated for corrosion resistance. They are used in furniture assembly, automotive parts, and other applications where strong threads are needed in thin materials.

11. Clip Nuts

Clip nuts, also called speed nuts, are designed to clip onto the edge of a sheet metal surface. They provide a secure, threaded fastening point without the need for additional tools. Clip nuts are typically made from spring steel and are great for use in environments with vibration, such as automotive assemblies or HVAC systems. They can be coated or plated to resist rust, and they are easy to install or remove, making them ideal for sheet metal applications.

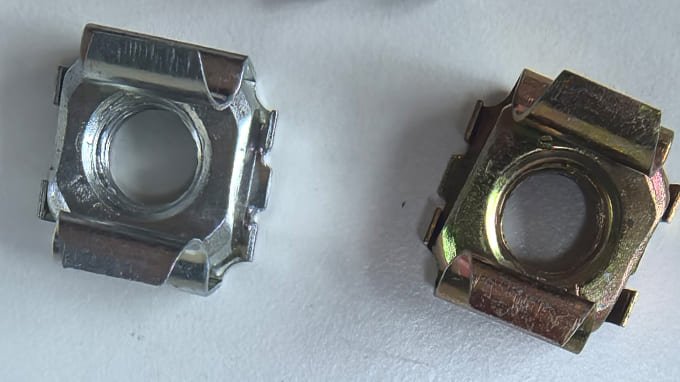

12. Cage Nuts

Cage nuts consist of a square nut housed inside a spring steel cage. The cage holds the nut in place and allows it to be inserted into square holes in metal frames. Cage nuts are especially useful in server racks or cabinets where bolts need to be installed or removed easily without the nut falling out. They are made from spring steel for the cage and carbon steel or stainless steel for the nut. These nuts are often zinc-plated for rust protection and are widely used in metal framing systems.

13. Barrel Nuts

Barrel nuts are designed to provide a strong, hidden connection in furniture and cabinetry. They are cylindrical with an internal thread that runs sideways through the barrel. Barrel nuts are used with bolts to secure two parts together, often in flat-pack furniture or wooden structures. They are typically made from steel, stainless steel, or brass. Barrel nuts are ideal for furniture, shelving, and other projects where a clean, flush finish is needed, as they sit completely inside the material, leaving no exposed hardware.

14. T-Nuts

T-nuts are T-shaped fasteners that are embedded into wood or metal to provide a strong, permanent thread for screws and bolts. These nuts are especially common in furniture and woodworking projects. T-nuts are usually made from carbon steel or stainless steel and are often zinc-plated to prevent rust. Their secure hold makes them ideal for hidden fastenings in furniture assembly.

15. Weld Nuts

Weld nuts are square or hex-shaped nuts designed to be welded onto metal surfaces, providing a permanent and secure fastening point. Weld nuts are made from carbon steel or stainless steel and are used in automotive manufacturing, structural steel projects, and other heavy-duty applications. They provide a reliable, fixed connection that can withstand heavy loads and stresses.

By choosing the right type of nut for your project, you ensure a strong, reliable connection that meets your specific needs. Whether you need to extend a threaded rod or fasten thin materials, these various nuts offer solutions for every kind of job.