Automotive

Hengrui Fastener Products for Automotive Industry

Shanghai Hengrui supplies automotive fasteners and precision metal parts for vehicle body, chassis, suspension, and engine systems. Our main products include flange bolts, wheel bolts, nuts, washers, and machined parts used in both OEM and aftermarket production. We use carbon steel, alloy steel, and stainless steel with coatings such as phosphate, zinc-nickel, and zinc-flake for corrosion protection.

Every batch is tested for dimension, hardness, and coating thickness before shipment. Production is managed under ISO 9001:2015 certification to guarantee quality and reliability.

Commonly Used Products

Hex Flange Bolts

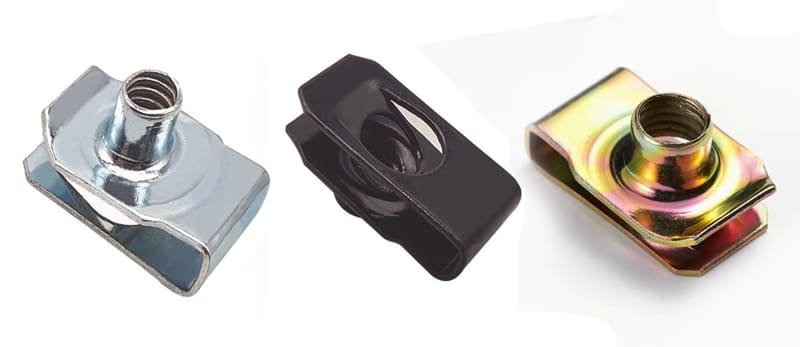

U clip nut

Threaded Rods and Studs

Wheel Bolt and Nut

Why Automotive Trust Shanghai Hengrui

Precision for Every Component

All fasteners are made with tight dimensional control and accurate threads to ensure smooth assembly and torque stability.

Strong Materials & Protective Coatings

We use alloy and carbon steels with phosphate, zinc-nickel, or zinc-flake coatings for rust and wear resistance.

Fast Prototyping & Stable Mass Production

Our flexible production lines allow quick sampling, and the same tools ensure consistency in volume production.

Quality Control & Traceability

Each batch is inspected for dimensions, hardness, and surface finish, ensuring reliable performance and full traceability under ISO 9001:2015.

Your Trusted Fastener Partner

Since 2020, our commitment to quality, customer satisfaction, and on-time delivery has been the foundation of our success. We continuously leverage our engineering knowledge, manufacturing capabilities, and innovative solutions to meet the unique needs of each project, ensuring that every fastener we deliver meets the highest standards.

Frequently Asked Questions

Automotive fasteners must meet tight tolerances, high vibration resistance, and strict safety standards to ensure consistent assembly and long-term reliability.

Alloy steel and carbon steel are most common for strength; stainless steel is used for corrosion-sensitive parts such as exhaust and trim components.

Yes, we provide prototype samples using the same process as mass production, so test results match final parts.

We use phosphate, zinc-nickel, and zinc-flake coatings tested for salt-spray resistance to ensure long-term protection against corrosion.

Custom fastener made easy

At HengRui, We turn complex Into Simple! Follow the following 3 steps to start today!

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

Get Solution & Quote

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

Approve for Mass Production

We will start mass production after getting your approval and deposit, and we will handle the shipment.

We Are Ready To Help You

- Get free sample!! Contact us today

- We will contact you within 24 hours

- Minimum order quantity: 1,000 Kg