Fasteners in harsh environments often fail due to corrosion. This leads to costly replacements and safety risks. Zinc-nickel plating offers a reliable solution that extends fastener lifespan and ensures compliance with global standards.

Zinc-nickel plating is an electroplated alloy coating containing 10–15% nickel, designed to enhance corrosion resistance and surface hardness for fasteners. Zinc provides sacrificial protection, while nickel improves barrier properties. This plating is especially effective in automotive, marine, and outdoor applications. It resists corrosion better than standard zinc plating and is often paired with chromate passivation and post-bake treatments for optimal durability.

Now let’s dive into how zinc-nickel plating works, its key benefits, and what to consider when specifying it for your fasteners.

What Is Zinc-Nickel Plating for Fasteners?

Zinc-nickel plating is an electroplated alloy coating applied to steel fasteners, typically containing 10–15% nickel. This alloy combines the sacrificial protection of zinc with the superior barrier and hardness properties of nickel. The result is a high-performance surface treatment that delivers long-lasting protection in harsh environments without requiring a thick deposit.

This alloy combines the best of both worlds—zinc offers sacrificial protection, while nickel acts as a durable barrier, especially in aggressive environments like coastal, automotive, or industrial applications.

How Zinc-Nickel Coating Protects Fasteners

During the electroplating process, zinc and nickel co-deposit onto the fastener’s surface in a controlled ratio. Nickel increases surface durability and corrosion resistance, particularly in environments containing chloride or salt exposure. Zinc acts as a sacrificial layer, corroding in place of the base metal. This dual protection approach significantly extends the life of fasteners in corrosive conditions. This synergy offers both immediate and long-term protection under aggressive exposure such as salt spray, road de-icers, and industrial humidity.

Most zinc-nickel plated fasteners receive an additional chromate passivation layer—commonly trivalent chromium—to enhance corrosion resistance and provide specific appearance finishes like clear, black, or iridescent. For high-strength fasteners, post-plate baking (typically within 4 hours after plating at 190–230°C) is applied to reduce the risk of hydrogen embrittlement.

Zinc-nickel plating is widely accepted as an environmentally friendly alternative to cadmium or hexavalent chrome coatings. It meets RoHS and ELV directives and is compatible with multiple substrate materials and fastening designs without causing galvanic issues.

When Should You Choose Zinc-Nickel Plating?

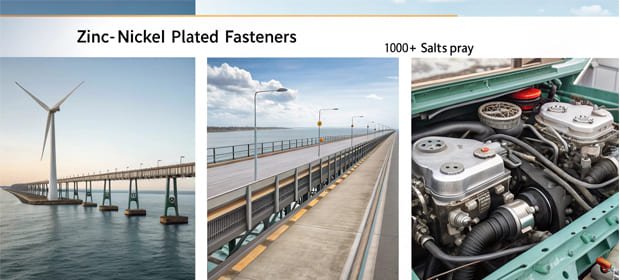

High-corrosion environments: Zinc-nickel plating is ideal for fasteners used outdoors, near the coast, or in areas exposed to road salts and de-icers. It delivers superior corrosion resistance compared to standard zinc coatings, making it well-suited for automotive, marine, energy, and infrastructure sectors.

High wear or surface stress applications: The nickel content significantly increases surface hardness, making it a smart choice for fasteners in load-bearing or moving parts, where wear resistance is critical. This durability enhances performance over long service cycles.

Regulatory requirements: In applications where cadmium or hexavalent chromium coatings are restricted by environmental regulations such as RoHS or ELV, zinc-nickel provides a compliant alternative without sacrificing performance. It’s particularly favored in European and North American markets for this reason.

Performance Benefits of Zinc-Nickel Coated Fasteners

Corrosion resistance: Zinc-nickel coatings typically offer 5–10 times greater corrosion resistance than conventional zinc plating in standardized salt spray testing (e.g., ASTM B117). Actual performance depends on nickel content, deposit quality, and post-treatment effectiveness, including chromate passivation and topcoats.

Deposit thickness: One of the key benefits is that zinc-nickel achieves excellent protection at relatively thin deposit thicknesses—typically between 5–12 microns—making it suitable for applications where weight or dimensional constraints are important, such as aerospace or tight-tolerance assemblies.

Hydrogen embrittlement: Electroplating introduces a risk of hydrogen embrittlement, especially in high-strength fasteners (e.g., Grade 8.8 and above). Baking the parts post-plating (often at 190–230°C for 2–4 hours) helps mitigate this risk. While baking reduces embrittlement, it may not eliminate it completely, so some critical applications may require alternative coatings or additional testing.

Process control sensitivity: Zinc-nickel coating performance relies on tight process control—nickel content, bath temperature, pH level, and current density must be precisely maintained. Inconsistent control can lead to uneven deposits, poor adhesion, or premature corrosion, so supplier qualification is essential.

About zinc-nickel Questions to Ask Your Fastener Supplier

When sourcing zinc-nickel plated fasteners, here are essential technical questions to ask:

- Nickel content and control:

What is the target nickel content in the deposit, and how is it controlled during production? - Embrittlement mitigation:

Do you perform bake treatments after plating, and what bake profile is recommended for our fasteners’ material and strength class? - Performance data:

Can you provide independent corrosion test results and relevant certifications for similar geometries and environments? - Process limitations:

Are there geometries or thread forms that limit zinc-nickel deposition, and how are complex shapes addressed?

If you’re unsure, you can share details of your fastener types, thread design, coating compatibility, and performance needs. A good supplier can then recommend precise specifications—from bake cycle profiles to trivalent chromate options—to meet your expectations.

Frequently Asked Questions (FAQ)

Is zinc-nickel better than zinc?

Yes. Zinc-nickel provides superior corrosion protection and surface hardness, lasting 5–10 times longer than traditional zinc plating under salt spray testing.

How long does zinc-nickel plating last?

Depending on the environment and post-treatment, zinc-nickel plating can last thousands of hours in salt spray tests—significantly outperforming zinc.

What is the difference between zinc-nickel and zinc plating?

Zinc-nickel contains 10–15% nickel, improving durability and resistance. Zinc plating offers only sacrificial protection and corrodes faster in harsh conditions.

Conclusion

Zinc-nickel plating offers superior protection, durability, and compliance for modern fastener applications. Whether you’re designing for harsh environments or meeting regulatory demands, it’s a smart choice. Need help choosing the right finish? Contact Hengrui for expert advice and customized zinc-nickel coated fasteners.