In automotive manufacturing and repair, selecting the right fasteners is key to ensuring vehicle safety and performance. With over 15 years of experience in the fastener industry, I’ll guide you through the most common fasteners used in automotive projects, including their sizes, coatings, and applications. Whether you’re working on vehicle assembly, repairs, or custom builds, this guide will help you understand the fasteners you need.

In automotive projects, the most common fasteners include Hex Flange Bolts, U Clip Nuts, Threaded Rods and Studs, and Wheel Bolts and Nuts. These fasteners are used to secure everything from body panels and engine components to wheels. Hex Flange Bolts and U Clip Nuts are often used in body assembly, while Threaded Rods and Wheel Bolts play crucial roles in securing critical parts like exhaust systems and wheels.

You can learn more about the fasteners designed specifically for automotive projects by exploring our dedicated page here: Automotive Fasteners, or highway and bridge fasteners information.

1. Common Materials Used for Automotive Fasteners

Before we dive into the types of fasteners, it’s important to know the materials they’re made of. Automotive fasteners need to be strong, lightweight, and resistant to rust due to exposure to moisture, heat, and chemicals. Here are the most common materials used:

- Stainless Steel: Stainless steel is widely used for automotive fasteners because it resists rust and corrosion. It’s strong and ideal for parts exposed to moisture or high heat.

- Carbon Steel: Carbon steel is used for fasteners that need to be strong but don’t require the same level of corrosion resistance as stainless steel. It is cost-effective and often treated to resist rust.

- Alloy Steel: Alloy steel is used for high-strength fasteners that need to withstand higher stresses, like those in engine components or critical structural parts.

- Zinc-Plated Steel: Zinc plating is commonly used for automotive fasteners to provide a layer of rust resistance, making them perfect for parts exposed to the weather or road conditions.

Now let’s look at the most common fasteners used in automotive projects.

2. Common Fasteners Used in Automotive Projects

2.1 Hex Flange Bolts

Hex Flange Bolts are commonly used in automotive assembly to secure parts like bumpers, fenders, and body panels. These bolts have a built-in flange that helps distribute pressure and ensures a tight fit.

- Coatings: These bolts are often zinc-plated or made from stainless steel to resist rust and ensure durability.

- Sizes: Common sizes for Hex Flange Bolts range from 1/4 inch to 1 inch in diameter, with lengths from 1 inch to 6 inches depending on the application.

- Applications: They are mainly used for securing automotive body parts and suspension components, ensuring a strong and stable connection.

Hex Flange Bolts are essential for holding various automotive parts together, especially where pressure and vibration are involved.

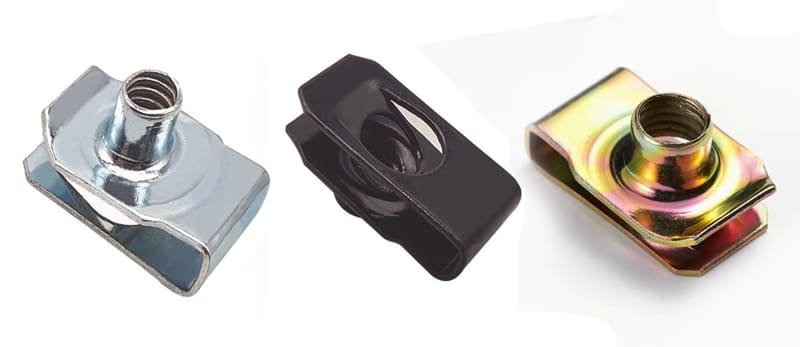

2.2 U Clip Nut

U Clip Nuts are used in automotive applications to secure parts in place without the need for threading a bolt into a nut. These fasteners are typically installed into pre-made holes and are used to secure panels, trim, and other parts that need to be easily detachable.

- Coatings: U Clip Nuts are usually made from galvanized steel or stainless steel to prevent rust and corrosion.

- Sizes: Common sizes for U Clip Nuts range from 1/4 inch to 1 inch in diameter, with lengths of 1 inch to 2 inches.

- Applications: They are often used in panel assembly, dashboard installations, and body trim fittings in cars and trucks.

U Clip Nuts are incredibly useful for parts that require regular adjustments or removal, offering flexibility and ease of use.

2.3 Threaded Rods and Studs

Threaded Rods and Studs are versatile fasteners used in automotive applications that require adjustable lengths. These fasteners are often used for engine components, exhaust systems, or brake systems.

- Coatings: These rods and studs are usually made from stainless steel or carbon steel, and they are often zinc-plated to prevent rusting, especially in high-moisture areas like the exhaust system.

- Sizes: Threaded Rods and Studs are available in a range of sizes, typically from 1/4 inch to 2 inches in diameter, with lengths ranging from 2 inches to several feet depending on the application.

- Applications: They are used in exhaust system installations, engine mounts, and suspension systems, where long, adjustable fasteners are needed.

Threaded Rods and Studs offer great flexibility in automotive assembly, especially when precise adjustments are needed.

2.4 Wheel Bolt and Nut

Wheel Bolts and Nuts are specifically designed to secure wheels to the vehicle. These fasteners are critical for safety, as they need to withstand heavy loads and road vibrations.

- Coatings: Wheel Bolts and Nuts are typically made from high-strength steel and coated with zinc or chrome to protect against rust and ensure they stay secure even in harsh weather conditions.

- Sizes: Common sizes for wheel bolts range from 1/2 inch to 1 inch in diameter, and they are typically shorter than other fasteners, with lengths from 1 inch to 2 inches.

- Applications: Wheel Bolts and Nuts are used for attaching wheels to hubs in cars, trucks, and other vehicles. They are essential for vehicle safety and performance.

Wheel Bolts and Nuts play a crucial role in ensuring that the wheels stay securely attached, even under heavy driving conditions.

FAQ

1. What fasteners are commonly used in automotive manufacturing?

The most commonly used fasteners in automotive manufacturing include Hex Flange Bolts, U Clip Nuts, Threaded Rods and Studs, and Wheel Bolts and Nuts. These fasteners are essential for securing body panels, engine components, and wheels.

2. What materials are best for automotive fasteners?

Alloy steel and carbon steel are most common for strength; stainless steel is used for corrosion-sensitive parts such as exhaust and trim components.

3. How do you ensure coating durability in automotive environments?

We use phosphate, zinc-nickel, and zinc-flake coatings tested for salt-spray resistance to ensure long-term protection against corrosion.

4. Do you support small-batch samples for testing?

Yes, we provide prototype samples using the same process as mass production, so test results match final parts.

Conclusion:

The fasteners we’ve discussed—Hex Flange Bolts, U Clip Nuts, Threaded Rods and Studs, and Wheel Bolts and Nuts—are crucial for the safety and performance of vehicles. These fasteners ensure that various parts, from body panels to wheels, stay securely attached. By selecting the right fasteners for your automotive projects, you ensure that your vehicle operates safely and efficiently.

Each fastener plays a unique role in maintaining the integrity of the vehicle. Whether you’re working on assembly, repairs, or custom builds, using the correct fasteners is essential for a safe, durable, and high-performance vehicle.