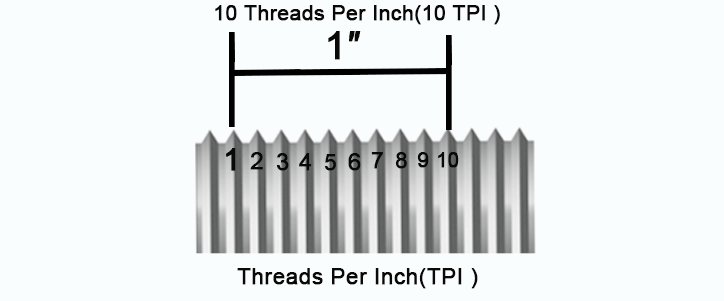

What is Threads Per Inch(TPI)?

Threads Per Inch, often abbreviated as TPI, refers to the number of threads across the one-inch of the thread length. It is a measurement method used to describe the thread density of threaded fasteners such as screws, nuts, and bolts. Only used in the US and other countries that follow the Inch threads system.

A higher TPI number indicates a finer thread, meaning the threads are closer together, Conversely, a lower TPI number indicates a coarser thread, meaning the threads are farther apart.

For example: 1/4″-20 bolt

Which means that the bolt has 1/4 inch diameter and has 20 threads per inch(TPI).

How to measure threads per inch?

To measure thread per inch, place the start of the caliper near the start of the thread on the screw or bolt head, and measure the number of threads in a one-inch section which is your TPI.

For the US Threads Per Inch Chart, refer to the table below, which includes UNC (coarse thread) and UNF (fine thread) standards for common bolt and screws sizes:

US Threads Per Inch Chart

| Diameter | UNC (Threads per Inch) | UNF (Threads per Inch) |

|---|---|---|

| #0 | 80 | 80 |

| #1 | 64 | 72 |

| #2 | 56 | 64 |

| #3 | 48 | 56 |

| #4 | 40 | 48 |

| #5 | 40 | 44 |

| #6 | 32 | 40 |

| #8 | 32 | 36 |

| #10 | 24 | 32 |

| #12 | 24 | 28 |

| 1/4″ | 20 | 28 |

| 5/16″ | 18 | 24 |

| 3/8″ | 16 | 24 |

| 7/16″ | 14 | 20 |

| 1/2″ | 13 | 20 |

| 9/16″ | 12 | 18 |

| 5/8″ | 11 | 18 |

| 3/4″ | 10 | 16 |

| 7/8″ | 9 | 14 |

| 1″ | 8 | 12 |

| 1-1/8″ | 7 | 8 |

| 1-1/4″ | 7 | 8 |

| 1-3/8″ | 6 | 8 |

| 1-1/2″ | 6 | 8 |

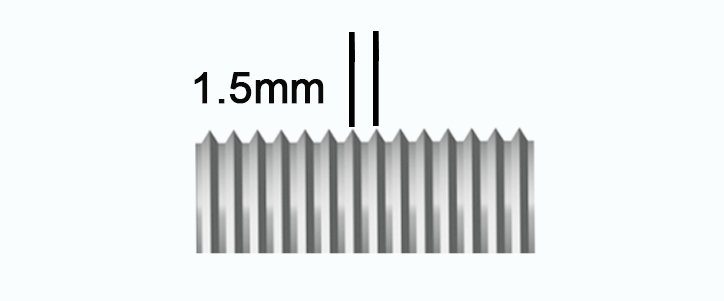

What is Thread Pitch?

Thread pitch is the distance between two adjacent threads on screws, bolts or nuts, measure distance in millimeters, for metric fasteners use Thread pitch instead of threads per inch (TPI).

For example: M10-1.5 bolt

Which means it has 10 mm diameter and 1.5 mm bolt thread pitch.

How to measure thread pitch?

Using a Caliper: Place the caliper parallel to the thread axis and measure the distance between adjacent peaks or valleys to get the pitch measurement.

Metric Thread Pitch Chart

| Size | Coarse Thread (mm) | Fine Thread (mm) |

|---|---|---|

| M1 | 0.25 | 0.2 |

| M1.2 | 0.25 | 0.2 |

| M1.4 | 0.3 | 0.2 |

| M1.6 | 0.35 | 0.2 |

| M1.8 | 0.35 | 0.2 |

| M2 | 0.4 | 0.25 |

| M2.5 | 0.45 | 0.35 |

| M3 | 0.5 | 0.35 |

| M4 | 0.7 | 0.5 |

| M5 | 0.8 | 0.5 |

| M6 | 1 | 0.75 |

| M8 | 1.25 | 1 |

| M10 | 1.5 | 1.25 |

| M12 | 1.75 | 1.5 |

| M16 | 2 | 1.5 |

| M20 | 2.5 | 2 |

| M24 | 3 | 2 |

| M30 | 3.5 | 2 |

| M36 | 4 | 3 |

| M42 | 4.5 | 3 |

| M48 | 5 | 3 |

Why TPI Matters?

If the thread spacing of bolts and nuts is different, it will lead to insufficient connection strength, difficulty in assembly, or easy loosening, seriously affecting the safety and durability of the structure. Choosing the correct thread spacing is key to ensuring a reliable mechanical connection.

How to choose the correct Thread Pitch?

Evaluate application requirements: Determine the mechanical loads, environmental conditions, and the required assembly speed.

Material Compatibility: Ensure the bolt material and the thread pitch are compatible with the materials being connected to avoid issues like corrosion or material deformation.

Standardization: Where possible, use standard thread pitches to ensure compatibility with existing tools and equipment.

If you have any questions or further assistance, feel free to contact us at Shanghai Hengrui Industry Co., Ltd. or call us at 0086-21-34201269.