The more that I meet with people and suggest fasteners from Hengrui, a question that repeatedly comes up is trying to stop those carriage bolts from turning. That’s the number one problem people have, so here are some answers to help you next time you have a project

*1. Use a matching square hole or drill a smaller hole than the carriage bolt, so it creates a tighter fit for the square neck that prevents rotation

*2. Place square-hole washers or locking washers and nuts over the bolt to keep it from rotating

*3. Serrated carriage bolts (not just with the smooth square neck) can increace additional gripping features

*4. Also, think about using a little glue between the carriage bolt and the material when you put it in place for that little extra “stick”

Knowing how to keep the carriage bolts from spinning is step one. Once you get that down, here are a few more related things that I have people ask me about. Something else that might help out the next time you’re working on your project.

Why Do Carriage Bolts Have Square Necks?

Carriage bolts have square necks for several important functional reasons:

- Self-locking mechanism: The square neck grips into wood or fits into a square hole, preventing rotation when tightening the nut.

- Single-sided installation: This feature allows installation and tightening from one side, ideal for limited access areas.

- Increased torque resistance: The square shape provides more surface area contact with the material.

- Secure fastening: The square neck bites into softer materials like wood, creating a more secure connection.

- Ease of alignment: Helps guide the bolt into the correct position, especially in pre-drilled square holes.

- Tamper resistance: The smooth domed head combined with the square neck makes it difficult to remove the bolt from the head side.

- Historical design: Originally used in carriage construction, this design allowed for a tight fit in reinforcing plates on wooden beams.

- Versatility: Works well in both wood and metal applications.

Can Carriage Bolts Support Heavy Loads?

Yes, carriage bolts are load-bearing fasteners, but their capacity can vary:

- Load-bearing capacity: Carriage bolts can bear loads, but may not be as robust as other types, like lag bolts.

- Shear strength: Generally higher than lag screws, with some bolts possessing shear strength of several thousand psi.

- Applications: Common in furniture assembly, metal bracket attachment, and wood-to-metal or wood-to-plastic connections.

- Material and grade: The load-bearing capacity depends on the material and grade, with Grade-5 and Grade-8 offering higher capacities.

What Are the Disadvantages of Carriage Bolts?

While versatile, carriage bolts do have some disadvantages:

- Limited range of sizes and materials: Available in a smaller range compared to other bolt types.

- May not suit all aesthetics: The rounded head may not fit all design preferences.

- One-sided accessibility: Can be a limitation in some situations.

- Difficulty in countersinking: The head design makes it challenging to create a flush surface.

- Limited material compatibility: May not work well with certain plastics or composite materials.

- Potential for wear: The square neck can wear away over time.

- Less versatile than some alternatives: Hex bolts offer more installation and removal options.

- May require additional components: Square neck washers might be needed for improved reliability.

- Not ideal for frequently disassembled structures: The square neck can damage the hole over time.

How to Loosen a Carriage Bolt?

Sometimes, you need to loosen a carriage bolt that has been tightly secured. Here are some methods:

- Use a wrench or socket on the nut: Focus on the nut, as the carriage bolt is designed to stay in place.

- Apply penetrating oil: If the bolt is rusty or stuck, apply penetrating oil like WD-40 to the threads and let it sit for a few minutes.

- Hold the head steady: Use pliers or a specialized carriage bolt holder to grip the rounded head.

- Use an impact wrench: For stubborn bolts, an impact wrench can provide the necessary force.

- Heat application: Carefully apply heat to the nut to break the bond, but be cautious around flammable materials.

- Cut the bolt: As a last resort, use a hacksaw or angle grinder.

What Can I Use Instead of Carriage Bolts?

Several alternatives can be considered based on your specific needs:

- Hex bolts: Easier tightening with a wrench.

- Lag bolts: Good for wood-to-wood connections.

- Machine bolts: Similar to hex bolts but with a more pronounced head.

- Threaded rods: Can be cut to custom lengths.

- Wood screws: Effective for lighter-duty wood connections.

- T-bolts: Useful in metal fabrication applications.

- J-bolts: Good for anchoring to concrete.

- Elevator bolts: Used in conveyor systems or agricultural equipment.

- Flange bolts: Have a built-in washer-like flange.

- Security bolts: Provide tamper-resistance.

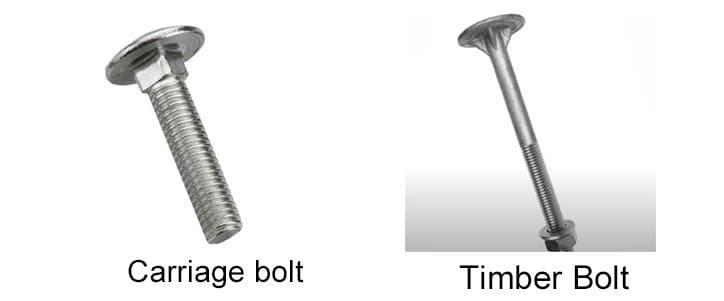

What Is the Difference Between a Carriage Bolt and a Timber Bolt?

While both bolts are used in construction, they have distinct differences:

- Carriage bolts: Have a smooth, rounded head and a square neck. Used for wood-to-wood or wood-to-metal connections, they require pre-drilled holes and a nut for fastening.

- Timber bolts: Typically larger and stronger, often with a hex head. Designed for heavy timber construction, they may be driven directly into wood or used with a nut.

Timber bolts are generally used in more heavy-duty applications like log home construction and large outdoor structures. In contrast, carriage bolts are more versatile but less robust.

Conclusion

Carriage bolts are used in many assemblies and projects all across the board because of how they are made and what they can be used for. Whether it’s wood cabinets you’re putting together, an outdoor structure you’re building, or a piece of machinery (automotive or something agricultural), they all use carriage bolts and they look good. It doesn’t matter if the carriage bolt is threaded with no threads, with a washer inserted, or no washer at all, each time you use them, they are always going to maintain a very solid and secure hold for you.

For more tips and advice on fasteners, feel free to visit our website or contact us directly. We’re here to help with all your fastening needs!