When you’re managing a large-scale project, whether in automotive manufacturing, oil & gas, or wind energy, the importance of the right fastener cannot be overstated. Standard fasteners often aren’t enough for specialized applications, and using them could lead to inefficiencies or costly failures. This is where a custom fastener manufacturer can add significant value, helping you meet specific performance, material, and durability requirements.

Working with a manufacturer who specializes in custom fasteners offers numerous advantages. Whether you have specific designs in mind or require assistance in creating a custom solution, a good manufacturer will help you achieve optimal performance, minimize downtime, and improve the overall efficiency of your project.

In this article, we’ll explore the benefits of custom fasteners and how the manufacturing process works, so you can make informed decisions for your next project.

What Are Custom Fasteners?

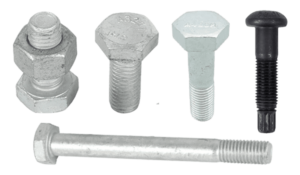

A custom fastener is designed to meet specific project requirements that standard fasteners simply can’t address. Off-the-shelf fasteners are typically mass-produced, which means they might lack the precision or specialized properties needed for unique applications. For example, you may require a fastener with unique dimensions, materials, or finishes to match a particular system or environmental condition.

In industries like oil & gas, wind energy, or automotive manufacturing, these unique needs are common. Custom fasteners ensure that your products fit perfectly, perform reliably, and withstand demanding conditions. These fasteners are tailored to meet specific performance standards such as resistance to high temperatures, corrosion, or vibrations. Whether it’s to ensure safety in public infrastructure projects or enhance performance in industrial systems, custom fasteners are essential for successful outcomes.

Hengrui is specializing in the manufacturing and exporting of bolts, screws, nuts, washers, and custom non-standard fastener, with many different materials, like carbon steel, stainless steel, brass, aluminum, titanium, special alloy steel, etc. The standard we can offer include IFI, DIN, BS, JIS, etc.

We offer custom fastener solutions for industries such as automotive, wind energy, and oil & gas, and are known for our flexibility in fulfilling even the most complex orders. Whether you need standard or non-standard bolts, our production lines and engineering expertise ensure your requirements are met with the highest standards. For inquiries or to place an order, feel free to contact them through company Contact Page.

How the Custom Fastener Manufacturing Process Works

Custom fastener manufacturing can vary based on the project requirements. At Hengrui, we regularly encounter two types of client needs:

1. Clients with Detailed Drawings

Some clients approach us with precise drawings and specifications for their fasteners. These blueprints typically include the exact dimensions, materials, finishes, and performance requirements for the fasteners. For these projects, we translate the provided designs into a high-quality finished product, ensuring every detail is met precisely.

2. Clients Without Drawings

On the other hand, many clients don’t have detailed drawings but have a general idea of the fastener they need. In these cases, we offer full design assistance, working closely with the client to understand their requirements. We then create custom drawings and prototypes, select the appropriate materials, and ensure that the final fastener meets all performance and durability criteria.

Whether you have clear specifications or need design support, the goal is always to ensure that the fasteners are tailored for the unique demands of your application.

Tailored Solutions for Unique Applications

One of the main advantages of working with a custom fastener manufacturer is the ability to tailor the fastener to meet specific needs. Standard fasteners can be a quick fix for general projects, but they often fall short when dealing with specialized applications that require precise tolerances, specific material properties, or enhanced performance.

For example, in high-stress environments like oil & gas fields or wind farms, fasteners need to withstand extreme temperatures, corrosive conditions, and mechanical stresses. Similarly, in automotive manufacturing, fasteners must be resistant to high vibrations and changing thermal conditions. Custom fasteners help to ensure that these projects run smoothly, safely, and efficiently.

By designing fasteners that meet your precise specifications, custom solutions enhance the overall performance and reliability of your projects, whether you’re dealing with standard or demanding conditions.

Improved Performance & Durability in Harsh Conditions

In industries where safety and reliability are non-negotiable, such as in offshore drilling or wind turbine construction, the fasteners used must be able to endure some of the harshest conditions imaginable. Custom fasteners are specifically engineered to handle extreme challenges, including:

- Corrosion resistance in humid or salty environments

- Strength to withstand high loads and pressure

- Long-term durability under constant wear and tear

Standard fasteners may corrode or fail under these harsh conditions, leading to downtime and increased costs. Custom fasteners, however, are designed to last, ensuring that your project stays on track with minimal risk of failure.

Precision & Consistency Across Large-Scale Projects

Large-scale projects often require hundreds or even thousands of fasteners. When managing such a large order, consistency and precision are crucial. Even small variations in fastener dimensions or material quality can result in project delays, safety issues, or increased costs.

Custom fastener manufacturers are equipped with advanced technology and rigorous quality control processes to ensure that every fastener meets exact specifications. Whether you’re sourcing a batch of fasteners for a large infrastructure project or need thousands of parts for a production line, the consistency provided by a custom manufacturer helps to reduce the risk of production delays and component failures.

Cost Efficiency & Bulk Discounts

While custom fasteners might seem more expensive than off-the-shelf solutions, the reality is that they can be more cost-effective in the long run. By working directly with a manufacturer, you can avoid the hidden costs associated with using non-standard fasteners, such as unexpected failures, replacements, and downtime.

Moreover, custom fastener manufacturers typically offer bulk discounts for large orders, making it even more affordable for large-scale projects. Purchasing in bulk allows you to get high-quality, tailored fasteners at a lower price, which helps improve the overall cost-efficiency of your project.

On-Time Delivery for Your Projects

Timely delivery is a key concern in any large project. Delays in receiving crucial components like fasteners can push back timelines, disrupt workflows, and ultimately impact the project’s success.

Custom fastener manufacturers, including Hengrui, typically have well-established logistics systems to ensure on-time delivery. This means that you can depend on your fasteners arriving exactly when you need them, avoiding delays and keeping your project on schedule.

Comprehensive Support for Design and Engineering

When you work with a custom fastener manufacturer, you’re not just buying a product; you’re also gaining access to expertise in design, engineering, and material selection. This support ensures that the fasteners are not only tailored to fit your needs but are also optimized for maximum performance, durability, and cost-efficiency.

From helping you design fasteners from scratch to providing advice on material properties and finishes, a good custom fastener manufacturer acts as a collaborative partner, working to ensure that your project requirements are met from start to finish.

Flexibility for Future Project Needs

As your project evolves, so will your fastener needs. The ability to adapt to new requirements or design changes is one of the key benefits of working with a custom fastener manufacturer. Whether your needs change over time or you discover new applications for your fasteners, a custom manufacturer can provide the flexibility necessary to keep up with your evolving project requirements.

This level of flexibility helps you stay ahead of the curve and ensures that your fastener solutions are always in line with the latest technological advancements and industry standards.

Summary

Custom fasteners are essential for industries requiring precision, durability, and reliability in demanding environments. Whether you have detailed drawings or need design assistance, a custom fastener manufacturer can provide tailored solutions that meet your exact specifications. Custom solutions help reduce downtime, improve performance, and enhance cost-efficiency for large-scale projects. Working with an experienced manufacturer ensures your fasteners perform reliably and are delivered on time, so your project stays on track.

If you’re looking for a reliable partner who can meet your fastener needs, contact a custom fastener manufacturer to discuss your requirements. The right solution is out there for you.