Are you looking to achieve a flawless drywall installation? Well, you’re in the right place. As an expert in fasteners, I’ve seen how the right choice of screws can make all the difference. Stick with me, and you’ll learn everything you need to know about drywall screws—what they are, the types, and best practices.

What Is a Drywall Screw?

Drywall screws are designed to securely attach drywall sheets to wood or metal studs. They are essential in both home and commercial construction, helping to keep drywall in place over time.

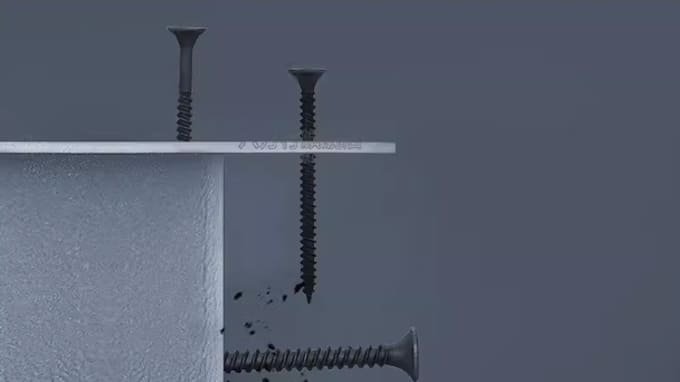

These screws have a unique bugle-shaped head. This head design allows them to sit flush with the drywall surface, ensuring a smooth, clean finish without tearing the paper. Drywall screws also feature deeper threads compared to regular screws. This thread design offers a strong grip, which prevents the screws from loosening or falling out.

Made from case-hardened steel, drywall screws are both strong and durable. They often have black or grey phosphate coatings to resist rust and add extra strength.

Drywall screws come in various sizes, typically ranging from 3.5 to 4.8 mm in diameter, or from 6# to 10#. These sizes are versatile and suitable for different types of drywall applications.

A key feature of drywall screws is their specific thread and tip angles. The thread crest angle is generally 60°, providing strong holding power. However, we can also customize it to 45° ± 5° to meet specific customer requirements. The tip angle of these screws is usually 25° ± 3°, which allows for easy penetration into drywall and studs.

Types of Drywall Screws

Choosing the right type of drywall screw can make all the difference. Here’s a breakdown of the main types:

- Coarse Thread (W-Type) Screws: Best suited for attaching drywall to wood studs, these screws have wider threads that grip wood firmly, preventing them from easily coming loose.

- Fine Thread (S-Type) Screws: Designed for use with metal studs, these screws have finer threads, which are sharper and easier to drive into metal without stripping, making them ideal for lightweight metal framing.

- Self-Drilling Screws: These screws are perfect for attaching drywall to heavier metal studs. Equipped with a drill bit end, they can create their own hole, eliminating the need for pre-drilling.

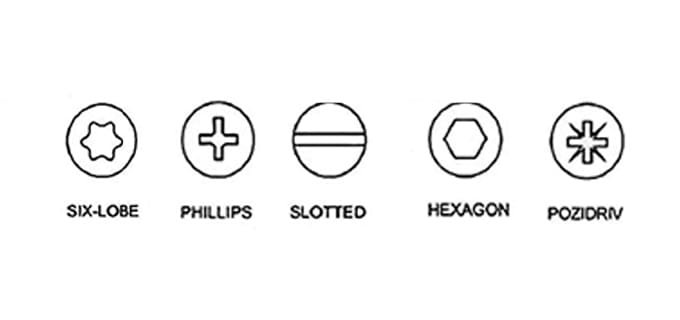

Drywall Screws Drive Types

The drive type of a drywall screw determines how easily it can be installed. Here are the main drive types:

- Phillips Drive

- Square Drive (Robertson)

- Torx Drive

- Slotted Drive

- Combination Drive

Advantages of Drywall Screws

Drywall screws have deeper threads than regular screws, giving them a strong and reliable grip. This ensures that drywall sheets stay securely attached to studs, preventing problems like sagging or falling off over time.

Due to their bugle head design, these screws can be placed flat on the surface. This can achieve a smooth and uniform surface, making it easy to paint or decorate, without causing any damage to the walls.

Installing drywall screws is simple. Their sharp points and deep threads allow them to penetrate drywall and studs quickly using a power drill or screw gun. This process doesn’t require pre-drilling, saving time and effort.

These screws cause less damage than nails. They leave only small indentations, making repairs easier and reducing the chance of cracks or other damage to the drywall surface.

What Is the Use of Drywall Screws?

Drywall screws are the best for installing drywall panels and have many other uses.

Drywall Installation: Drywall screws are mainly used to secure drywall sheets to wood or metal studs and ceiling joists. They provide a strong hold, which keeps the drywall from coming loose and ensures it stays stable over time.

Repairing Nail Pops: These screws are also great for fixing nail pops. Nail pops are those small bumps that appear on walls due to old, wide-head nails pushing out. Drywall screws offer a more secure fix, reducing the chance of these problems happening again.

Light Woodworking Projects: The coarse threads make drywall screws suitable for light woodworking tasks, especially when dealing with softwood. They’re often used by cabinet installers for constructing and securing cabinets.

Versatile Fastening: Beyond drywall, these screws can be used for hanging shelves, attaching furring strips, and even minor wood repairs. Their versatility makes them a handy addition to any toolbox.

When Not to Use Drywall Screws?

While drywall screws are versatile, they aren’t suitable for all situations:

Outdoor Applications: Drywall screws should not be used outdoors, particularly in moist or humid environments, as they are prone to rust. Projects like fencing or decking are better suited to galvanized or stainless steel fasteners.

Heavy Structural Support: Avoid using drywall screws for heavy-duty structural applications, like installing ceiling fans or securing electrical boxes. These require stronger fasteners to ensure safety and stability.

High-Stress Applications: Drywall screws are brittle under high stress and may break. Avoid using them in applications that involve significant loads or movement, like stair framing or handrails.

How Long Should Drywall Screws Be for a Ceiling?

For ceiling installations, the length of the drywall screws is crucial. For 1/2″ drywall panels, using screws that are 1-1/4″ to 1-5/8″ in length is recommended. These lengths are sufficient to penetrate the drywall and secure into the studs, ensuring a firm hold.

Shorter screws (1-1/4″) are easier to install and less likely to pop out, while longer screws (1-5/8″) offer more holding power. For thicker 5/8″ drywall, opt for screws that are 1-5/8″ to 2″ in length.

How Many Screws Per Sheet of Drywall?

The number of screws you need per sheet of drywall depends on the panel size and where it’s being installed.

Standard Size: For a standard 4×8-foot sheet, you’ll typically need around 32 screws. Place screws every 12 inches along the edges and every 12-16 inches in the center area.

Ceiling Installation: When installing drywall on a ceiling, you might use more screws to ensure a firm hold. Spacing screws closer together, about 8 inches apart, can provide extra support and prevent sagging.

How to Drive Drywall Screws?

Driving drywall screws is easy if you follow these steps:

- Choose the Right Tool: Use a drywall screw gun or a cordless drill with a drywall bit. A screw gun offers better depth control, ensuring that screws sit flush with the drywall surface.

- Prepare the Drywall: Mark the location of studs and ensure the drywall is pressed firmly against the studs. Place screws about 6.5 mm from the edges.

- Set the Depth: Adjust the screw gun to the correct depth to prevent the screws from piercing the drywall paper. This helps maintain a clean surface, ready for finishing.

- Drive the Screws: Place a drywall screw on the screw gun’s magnetic tip. Align it with the stud and apply steady pressure as you drive it in. Stop when the screw head is flush with the drywall surface.

- Check Spacing: Ensure screws are spaced correctly along the edges and throughout the drywall sheet to secure a solid installation.

Conclusion

Drywall screws are a great choice for many building and repair jobs. They are strong and reliable, making them useful for a variety of tasks. Knowing the different types, sizes, and how to use them correctly will help you get a professional look and finish.

At Shanghai Hengrui Industry Co., Ltd, we offer a wide range of high-quality drywall screws to meet all your project needs. Ready to start your next drywall project? We’ve got you covered!