Finding the right fastener for heavy-duty tasks is crucial. Many screws can’t handle the load, causing frustrating failures and unsafe conditions. As a fastener expert, I understand the need for reliable solutions. That’s where lag screws come in. These robust fasteners are specifically designed for high-stress applications, providing secure and lasting connections.

At Shanghai Hengrui, we offer high-quality lag screws built for strength and durability, ensuring your projects are safe and stable.

What is a Lag Screw?

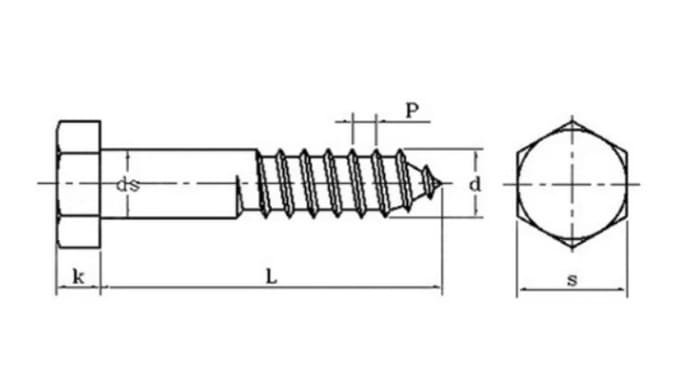

Lag screws, sometimes known as lag bolts or coach screw, are heavyweight fasteners that excel in connecting heavy wood and other materials that need to support a lot of weight. These screws have a special design: they feature a thick, hexagonal head that you need a wrench to tighten, which is different from regular screws.

The key feature of lag screws is their coarse threads. These threads dig deep into wood and other materials, offering a strong grip that ensures a secure, long-lasting hold. Lag screws are particularly popular in construction and carpentry because they provide the firm fastening needed for structures and large wooden projects.

Lag screws come in various sizes, measured by diameter and length. Common diameters range from 1/4 inch to 1 inch, and lengths can vary from 1 inch to more than 12 inches. The specific size you need will depend on the thickness of the materials and the load requirements of your project.

Lag Screws vs. Wood Screws

Lag screws are bigger and thicker than wood screws and usually have a hexagonal head, which you need a wrench or ratchet to install. They have coarse threads that run most of the way down the shaft and need to be driven into pre-drilled holes. This makes them perfect for heavy-duty tasks. On the other hand, wood screws are smaller, with a tapered point and finer threads. These threads let wood screws cut their own hole as they go into the wood. This self-threading feature makes wood screws easier to use for lighter tasks, without the need to drill a hole first.

In short, if you’re working on big construction projects or need a strong fastening solution, go with lag screws. For lighter, everyday woodworking tasks, wood screws will do the job.

The Material of Lag Screws

Lag screws are typically made from a few common materials, each suited for different environments:

- Carbon Steel Lag Screws: This is the most common material used for lag screws. It provides excellent strength and durability, making it suitable for most indoor applications. Carbon steel lag screws are often coated with zinc or galvanized for corrosion resistance.

- Stainless Steel Lag Screws: Stainless steel lag screws are preferred for outdoor or marine applications where rust and corrosion are a concern. They offer superior resistance to harsh environmental conditions, ensuring longevity and durability.

- Silicon Bronze Lag Screws: This material is used in specialized applications, such as boat building, where both strength and resistance to corrosion are critical. Silicon bronze offers better corrosion resistance than brass and is ideal for use in saltwater environments.

What Are the Advantages of Lag Screws?

Lag screws offer several advantages, making them a preferred choice for heavy-duty fastening tasks. Their primary benefit is strength. Designed for high-stress applications, lag screws can handle significant loads without breaking, ensuring the stability of structures over time.

Another advantage is their resistance to corrosion. Many lag screws are made from high-carbon steel and are often galvanized, which helps protect them from rust and corrosion. This makes them suitable for use in outdoor or humid environments, where they can last for decades without losing their integrity.

Lag screws are also versatile. They are used in a wide range of applications, from woodworking and construction to securing metal to wood or masonry. Their strong grip and load-bearing capacity make them suitable for both residential and commercial projects.

Finally, lag screws are user-friendly. With their hexagonal head, they are easy to install using common tools like wrenches or ratchets. This allows for a secure fit with high torque application, making the installation process straightforward and efficient.

What Are Lag Screws Used For?

Lag screws are strong and durable, making them perfect for many heavy-duty tasks:

Construction Uses: Lag screws are often used to secure beams, posts, and other parts of large timber structures. Lag screws are great for attaching decks boards , as well as fastening posts for fences, gates, and railings. Lag screws also help secure tracks for overhead garage doors.

Woodworking and DIY Projects: In woodworking, lag screws are excellent for joining thick pieces of wood, like those used in building workbenches or heavy furniture. They are also used to attach shelves, cabinets, and other fixtures to wooden studs, and to strengthen wooden structures like stairs and fences.

Industrial and Commercial Uses: Lag screws are important in industrial settings for securing heavy machines and equipment to the floor. They are used to anchor large shelving and storage units, and to secure wooden pallets and crates for shipping. These screws also play a role in building timber retaining walls and structures to control erosion.

How to Use Lag Screws?

Using lag screws is simple if you follow these steps:

- Prepare the Materials: Line up the pieces you want to join and hold them in place with clamps.

- Drill a Pilot Hole: Use a drill bit that is a bit smaller than the lag screw. This will guide the screw and make it easier to drive in. Make sure the hole is deep enough for the entire screw.

- Install the Screw: Put the lag screw into the pilot hole. Then, use a wrench or power drill to turn the screw until it is tight.

- Check for Tightness: Make sure the screw head is even with the surface. Don’t tighten it too much, as this could damage the material.

How to Choose a Lag Screw?

Choosing the right lag screw depends on several factors:

- Diameter and Length: The diameter should match the load requirements, while the length should allow the screw to penetrate through the materials and provide adequate anchorage.

- Material and Coating: Choose carbon steel for indoor use, stainless steel for outdoor or corrosive environments, and silicon bronze for specialized applications. Consider galvanized or coated screws for additional corrosion resistance.

- Thread Type and Point Style: Opt for coarse threads for better grip in wood. The point style should match the installation needs; a standard semi-cone point is usually sufficient.

- Application Considerations: Evaluate the load and material compatibility. For heavy-duty tasks, use thicker and longer screws that can handle the stress.

Conclusion

Lag screws are strong and reliable fasteners that can be used for many different jobs. Whether you’re building a deck, putting together furniture, or working on a big construction project, choosing the right lag screws is important. The right screws will help make sure your work is solid and lasts a long time.

At Shanghai Hengrui Industry Co., Ltd., we offer a variety of top-quality lag screws to meet your project needs. For more information, feel free to contact to us at info@hrfastener.com or visit our website.