Do you ever find yourself confused by the vast array of fasteners available? You’re not the only one. I get emails from people asking about screws and fasteners to use – everyone gets confused. One question that comes up again and again is machine screws. If you’ve ever been puzzled by these handy little fasteners, keep reading—I’ve got you covered

What is a Machine Screw?

A machine screw is a type of threaded fastener specifically designed for use in machinery and mechanical applications. Unlike bolts, machine screws are typically smaller, often with a diameter under M10 or 3/8″. Their uniform threading allows them to be driven into pre-tapped holes or used with nuts to secure various components.

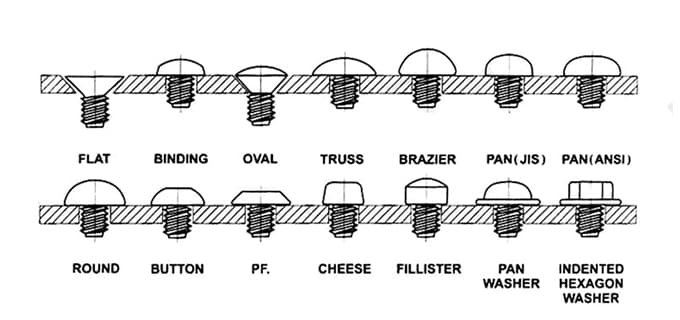

Machine screws are defined by two main components: a head and a fully threaded shank. The head is where the screwdriver or tool engages, and it can come in various shapes like flat, round, or hexagonal. The fully threaded shank, on the other hand, ensures a strong and secure hold within the pre-tapped holes or when paired with a nut.

These screws are crucial in applications ranging from precision electronics to heavy machinery. Depending on the intended use, they can be made from various materials, each offering specific strengths and corrosion resistance.

How Machine Screws Differ from Bolts?

It’s a common question, and I’m glad you asked. While both machine screws and bolts are threaded fasteners, they serve different purposes and are used in different ways.

First, the head design differs. Machine screws typically have slotted or Phillips heads, meaning they’re driven with a screwdriver. Bolts, on the other hand, usually have a hex head, which requires a wrench or socket for tightening.

Next, there’s the threading and length. Machine screws are fully threaded and generally shorter than bolts, often less than 1 inch. Bolts are usually longer and may have a partially threaded shank, which provides additional strength in shear applications.

Lastly, the installation method sets them apart. Machine screws are often used in pre-tapped holes, making them ideal for secure connections without the need for a nut. Bolts are typically used by passing through the material and securing with a nut on the opposite side.

The Material of Machine Screws

The material selection for machine screws is critical, as it directly affects their performance, durability, and suitability for specific environments. Here are the most common materials:

- Stainless Steel

- Aluminum

- Brass

- Carbon Steel

- High-Carbon Steel

- Bronze

- Titanium

- Nickel-Copper Alloys

The Different Types of Machine Screws

Machine screws come in a variety of types, each tailored for specific applications. Here are some common types you’ll encounter:

- Flat Head Machine Screws: Designed to be countersunk, leaving a flush surface. Ideal for a neat, professional finish.

- Pan Head Machine Screws: Feature a rounded top, providing a larger surface area for better load distribution.

- Round Head Machine Screws: With a dome-shaped head, they are often chosen for their aesthetic appeal.

- Hex Head Machine Screws: Designed for high-torque applications, providing a secure grip when tightened with a wrench.

- Socket Head Machine Screws: Have a cylindrical head with a hexagonal recess, perfect for tight spaces.

- SEMS Machine Screws: Come pre-assembled with a washer, simplifying the installation process.

- Type F Machine Screws: Thread-cutting screws that create their own threads, suitable for softer materials.

- Tamper-Resistant Machine Screws: Feature unique head designs to prevent unauthorized removal.

- Metric Machine Screws: Follow the metric system for sizing and threading, commonly used in international applications.

- Stainless Steel Machine Screws: Ideal for applications exposed to moisture or harsh environments.

Machine Screws Drive Types

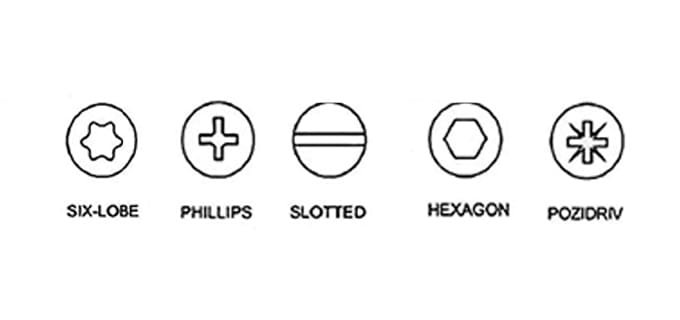

Machine screws feature various drive types, each accommodating different tools and applications:

- Slotted Drive: A simple horizontal slot for flat-head screwdrivers.

- Phillips Drive: Cross-shaped for better torque and reduced slipping.

- Pozidriv Drive: An enhanced Phillips design that offers even better grip.

- Torx Drive: A six-pointed star shape for high-torque applications.

- Hex Socket (Allen) Drive: A hexagonal recess for use with Allen wrenches.

What Are Machine Screws Used For?

Machine screws are incredibly versatile and used across a wide range of industries. Here are some of the most common applications:

- Machinery and Industrial Equipment: From engines to large-scale industrial machinery, machine screws provide secure connections that withstand vibration and heavy loads.

- Electrical and Electronics: Their small size and precise threading make them ideal for securing components in devices, from electrical connections to the fabrication of intricate electronic devices.

How to Use Machine Screws?

Using machine screws effectively involves a few key steps:

- Preparing the Hole: Drill a hole slightly smaller than the screw’s diameter in the material. If the material is hard like metal, tap the hole with a matching thread size.

- Selecting the Right Screw: Choose a screw length that allows 2-3 threads to protrude beyond the material. Pick a head style and drive type that suits your application.

- Installing the Screw: Apply a thread-locking compound if needed, then insert the screw into the pre-drilled hole and tighten it with the appropriate tool. Avoid over-tightening to prevent damage.

How to Measure Machine Screws

Measuring machine screws is straightforward but crucial for selecting the right one. Start by measuring the length from the bottom of the head to the tip. For countersunk screws, measure from the top of the head to the bottom. Additionally, measure the diameter and thread pitch. The diameter refers to the width of the threaded part, while the thread pitch is the distance between adjacent threads, typically measured as threads per inch.

Metric Machine Screws Size Chart:

| Specification | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M8 | M10 |

|---|---|---|---|---|---|---|---|---|

| Thread Diameter (mm) | 2.5 | 3.0 | 3.5 | 4.0 | 5.0 | 6.0 | 8.0 | 10.0 |

| Thread Diameter (inches) | 0.098 | 0.118 | 0.138 | 0.157 | 0.197 | 0.236 | 0.315 | 0.394 |

| Thread Pitch (Coarse) | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | 1.25 | 1.5 |

| Thread Pitch (Fine) | 0.35 | 0.35 | 0.35 | 0.5 | 0.5 | 0.75 | 1.0 | 1.25 |

Inch Machine Screws Size Chart:

| Specification | 4# | 5# | 6# | 8# | 10# | 12# | 1/4 | 5/16 | 3/8 |

|---|---|---|---|---|---|---|---|---|---|

| Thread Diameter (inches) | 0.112 | 0.125 | 0.138 | 0.164 | 0.190 | 0.216 | 0.250 | 0.312 | 0.375 |

| Thread Diameter (mm) | 2.84 | 3.18 | 3.51 | 4.17 | 4.83 | 5.49 | 6.35 | 7.92 | 9.53 |

| Thread Pitch (Coarse) | 40 | 40 | 32 | 32 | 24 | 24 | 20 | 18 | 16 |

| Thread Pitch (Fine) | 48 | 44 | 40 | 36 | 32 | 28 | 28 | 24 | 24 |

Conclusion

Machine screws are small, everyday components that are used in countless applications. Whether you’re in the automotive business, electronics, or heavy machinery, knowing which machine screws to use can make the difference between things working and not working. When you pick the right material, type, and install them correctly, you’ll have a secure and reliable connection every time.

Feel free to reach out to us at Shanghai Hengrui Industry Co., Ltd for any of your machine screws needs. We are here to help you find the perfect solution for your applications.