When working with bolted connections in industries like construction, automotive, aerospace, or heavy machinery, selecting the right bolt is critical for both safety and performance. In this article, I’ll walk you through the differences between black bolts and HSFG (High Strength Friction Grip) bolts to help you understand which one is the best choice for your application.

Black bolts are made from low-strength steel and are suitable for static load applications. They rely on shear resistance for load transfer and are cost-effective for simple structures. In contrast, HSFG bolts are made from high-strength steel alloys, transferring loads through friction and preloading. They are ideal for dynamic applications and provide enhanced stability, making them perfect for structures subject to fluctuating loads or vibrations.

Now that we’ve covered the basic differences, let’s dive deeper into the advantages and applications of each type of bolt, helping you make an informed decision for your next project.

What Are Black Bolts?

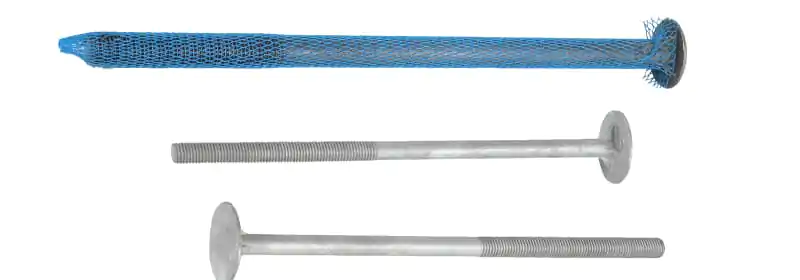

Black bolts are typically made from low-strength steel alloys like Q235 steel. These bolts are commonly used in general construction applications where high strength is not essential. They come with a black oxide finish, providing basic corrosion resistance but offering little in terms of additional strength or durability.

Black bolts are available in grades 4.4 to 8.8, making them suitable for applications with static loads that don’t require high tensile strength. They transfer loads mainly through shear resistance and bearing against the hole walls. While black bolts perform well in simple structures, they’re not ideal for environments where dynamic stresses, vibrations, or fluctuating forces are present.

Due to their low cost, black bolts are often chosen for less demanding projects. However, these bolts might require frequent maintenance, as they’re more prone to loosening over time.

What Are HSFG Bolts?

HSFG bolts are made from high-strength steel alloys such as 45# steel or 20MnTiB steel. These bolts have much higher tensile strength compared to black bolts. Through special processes like quenching and tempering, or alloying, HSFG bolts are made more resistant to high stresses, giving them better overall strength and durability.

The main difference between HSFG bolts and black bolts lies in how they transfer loads. HSFG bolts are preloaded, creating a frictional grip between the connected components. This friction helps prevent slippage and ensures a stable, high-strength connection that can handle dynamic loads, vibrations, or seismic forces. As a result, HSFG bolts are perfect for critical applications such as bridges, high-rise buildings, and aerospace components.

Black Bolts vs. High Strength Bolts

While black bolts are made from lower-strength materials and are suitable for static loads, HSFG bolts are made from medium-carbon or high-strength steel alloys, typically rated from 8.8 to 10.9 or higher. High-strength bolts are designed to handle higher dynamic or cyclic loading. They perform much better under stress and fatigue, ensuring more reliable, long-lasting connections.

The main benefit of high-strength bolts is their ability to perform under stress and maintain stability over time. When subjected to constant loading and unloading, HSFG bolts provide a much safer and more durable connection.

When Should You Use HSFG Bolts?

HSFG bolts are essential when your structure will face vibrations, fatigue, or reversing loads. The preloading of the bolt ensures that the components stay tightly in place, even under high stress. These bolts are particularly useful for critical structures such as bridges, high-rise buildings, or heavy machinery that experiences constant stress.

Advantages of Black Bolts

Black bolts are a cost-effective solution for simple applications that don’t face high dynamic stresses. They’re easy to install and less expensive than HSFG bolts. Common uses include steel frame construction, fencing, and general infrastructure projects that deal with static loads.

While black bolts don’t offer the same level of strength or stability as HSFG bolts, they’re a great choice for projects where cost is a concern and the need for vibration resistance or fatigue performance is not as important.

Advantages of HSFG Bolts

The key advantage of HSFG bolts lies in their superior performance under dynamic loads. They are designed to handle high-stress environments where vibrations, seismic forces, or fluctuating temperatures are common. When preloaded, they reduce stress during each loading cycle, helping to minimize the risk of failure. The friction grip ensures the connected components remain securely fastened, even in extreme conditions.

HSFG bolts are critical for projects where safety, reliability, and long-term durability are essential—such as in bridge construction, high-rise buildings, and aerospace applications.

Conclusion

To summarize, black bolts and HSFG bolts are designed for different types of applications. Black bolts are ideal for simple, cost-sensitive projects where the loads are static. In contrast, HSFG bolts are the go-to option for dynamic, high-stress environments that require long-lasting and stable connections.

Choosing the right bolt for your project is crucial for ensuring both performance and safety. If you’re unsure which one to select, feel free to contact us for expert advice. We’re here to help you make the best decision for your needs.