Ever found yourself in the fastener aisle, puzzled by the terms “zinc plated” and “galvanized”? Trust me, you’re not alone! At Hengrui, we’re all about making fastener choices easy and informed. Let’s unravel the mystery together.

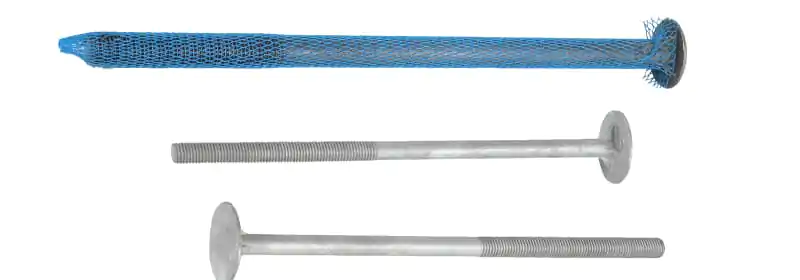

*Zinc plated fasteners have a thin, shiny coating of 5-25 μm (0.2-1.0 mil), providing basic corrosion resistance, ideal for indoor use. Galvanized fasteners are hot-dipped in molten zinc, resulting in a thicker, rougher coating of 43-86 µm (1.7-3.4mil). While more expensive, galvanized parts last longer outdoors, offering superior rust protection for harsh environments.

Now we’re going to go deep on “zinc plated” and “galvanized.” By the end of this, you won’t wonder about the difference between “zinc plated” and “galvanized” anymore, and which one suits your needs best.

What is Zinc Plated and Galvanized?

Zinc Plated

Zinc plating, also known as electro-galvanizing, involves applying a thin layer of zinc to steel or iron using an electrical current. This process is done by immersing the metal in a cold chemical solution of zinc and using an electrical current to deposit the zinc onto the surface.

- Coating Thickness: Typically ranges from 5 to 25 micrometers (μm).

- Appearance: Shiny and smooth finish.

- Corrosion Resistance: Provides some rust protection but is less resistant than galvanized coatings. Suitable for indoor applications or environments with low humidity.

- Cost: Generally cheaper and easier to weld compared to hot-dip galvanizing.

Galvanized

Galvanization involves applying a protective zinc coating to steel or iron to prevent rusting. The most common method is hot-dip galvanizing, where metal parts are fully submerged in a bath of molten zinc.

- Coating Thickness: Typically starts at 45 μm and can exceed 100 μm.

- Appearance: Dull gray and slightly rough finish.

- Corrosion Resistance: Offers superior corrosion protection due to the thicker zinc coating. Ideal for outdoor or harsh environments, such as marine or industrial applications.

- Cost: More expensive than zinc plating but provides better long-term protection against rust.

What are the Disadvantages of Zinc Plating?

While zinc plating is cheaper and provides some corrosion protection, it’s generally less effective and durable than hot-dip galvanizing. Here are some key disadvantages:

- Thinner coating: Zinc plating typically produces a much thinner coating (5-25 μm) compared to hot-dip galvanizing (45-100+ μm). This results in less corrosion protection.

- Lower corrosion resistance: Due to the thinner coating, zinc plated items have lower corrosion resistance compared to hot-dip galvanized items, especially in outdoor or harsh environments.

- Shorter lifespan: Zinc plated items generally have a shorter lifespan in corrosive environments compared to galvanized items.

- Limited outdoor use: Zinc plating is more suitable for indoor applications or environments with low humidity. It’s not ideal for outdoor use or harsh environments.

- Less durable: The thinner zinc coating is less durable and can wear off more quickly than galvanized coatings.

- No metallurgical bond: Unlike hot-dip galvanizing, zinc plating doesn’t create a metallurgical bond between the zinc and the base metal. It only adheres to the surface.

- Temperature limitations: Zinc plated items may not perform well in high-temperature applications.

- Aesthetic changes: While initially shiny, zinc plated surfaces can dull over time.

- Not suitable for threaded fasteners: The thin coating doesn’t provide adequate protection for threaded areas, which are prone to corrosion.

- Less effective sacrificial protection: The thinner zinc layer provides less sacrificial protection to the base metal compared to galvanized coatings.

Galvanized vs. Zinc Plated: Which is the Better Choice?

Hot-dip galvanized is generally better than zinc plated for most applications, especially those requiring superior corrosion resistance. Here’s why:

- Corrosion Resistance: Hot-dip galvanized is significantly better at resisting corrosion, especially in outdoor or harsh environments. Zinc plated offers some rust protection but is less resistant.

- Coating Thickness: Hot-dip galvanizing: Minimum 45 μm, can exceed 100 μm. Zinc plating: Typically 5-25 μm.

- Durability: Hot-dip galvanized products can last decades without showing signs of rust in outdoor environments. Zinc plated items have shorter lifespans in corrosive environments.

- Application: Hot-dip galvanized is ideal for outdoor use, marine environments, and industrial applications. Zinc plating is suitable for indoor applications or environments with low humidity.

- Cost: Hot-dip galvanizing is more expensive but provides better long-term protection. Zinc plating is generally cheaper and easier to weld.

- Appearance: Hot-dip galvanized has a dull gray, slightly rough finish. Zinc plated has a smooth, shiny finish.

- Bonding: Hot-dip galvanizing creates a metallurgical bond between zinc and steel. Zinc plating adheres to the surface but doesn’t form a metallic bond.

Will Zinc Plated Fasteners Rust?

Yes, zinc plated fasteners can rust. Their thinner coating offers less protection in corrosive environments. Over time, especially when exposed to moisture, zinc plated items will eventually rust, particularly in outdoor or harsh conditions. The thinner zinc coating wears off faster compared to the thicker hot-dip galvanized coating. For long-term rust protection, especially in challenging environments, hot-dip galvanizing is a more effective choice.

Conclusion

So, what’s the bottom line? If you’re looking for cost-effective fasteners for indoor use, zinc plated might be the way to go. However, for superior corrosion resistance and durability, especially in outdoor or harsh environments, galvanized fasteners are the better choice.

Understanding the differences between zinc plated and galvanized fasteners can help you make an informed decision, ensuring your projects stand the test of time. If you have more questions, feel free to reach out to us at Shanghai Hengrui Industry Co., Ltd. We’re here to help you find the perfect fasteners for your needs!

For more information, visit our website or contact us at info@hrfastener.com.