Are washers necessary for structural bolts? That’s a question I get a lot. If you’re working with steel-to-steel connections or designing a building, you’re likely wondering about the role washers play in structural bolting. Let’s dive in and clear up the confusion.

Structural bolts like ASTM A325 or A490 generally don’t need washers unless specified. For A490 bolts, washers are required under both the head and nut if the material’s yield strength is below 40 ksi. Washers are also needed for oversized or slotted holes to ensure proper load distribution.

You may be wondering why washers are needed in the first place. Well, it’s all about creating a reliable, stable connection. Washers help distribute the load more evenly, prevent the bolt head or nut from embedding into softer material, and ensure the bolt remains tight under pressure. Now that we’ve scratched the surface, let’s get into the nitty-gritty details about structural bolts, washers, and the best practices you should follow in your projects.

What is a Structural Bolt?

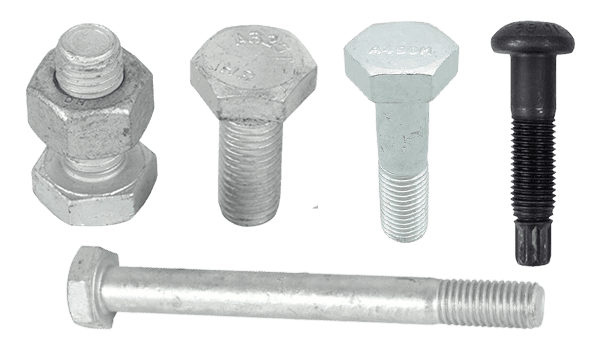

Structural bolts are high-strength fasteners specifically designed to join steel elements in structural applications like buildings, bridges, and towers. These bolts are built to withstand heavy loads, which is why they are essential for projects where stability and strength are key. You’ll often find them used in steel-to-steel connections such as beam-to-column, splice connections, and joints that are subjected to high tensile forces.

There are different types of structural bolts, with ASTM A325 and A490 being two of the most common standards. Modern structural bolts are often governed by ASTM F3125, which combines earlier standards like A325, A490, and others. The main difference between these bolts lies in their strength—A490 bolts are stronger than A325 bolts. Typically, these bolts are heavy hex head bolts, designed for high-strength applications.

- A325 bolts: These bolts have a tensile strength of around 120 ksi and a yield strength of 92 ksi.

- A490 bolts: These have a higher tensile strength of about 150 ksi and a yield strength of 130 ksi, making them suitable for more heavily loaded applications.

Both types of bolts are designed for specific use cases in structural steel connections, where high clamping force and reliability are essential. You’ll see them used in steel building frames, bridges, and other critical infrastructure projects that require secure and durable connections.

When Do You Need Washers for A490 Bolts?

Washers are essential for ensuring proper installation and maintaining the integrity of structural joints, especially when using A490 bolts. According to industry guidelines, washers are mandatory in the following scenarios:

- When the connected material has a yield strength less than 40 ksi: If you’re working with materials that have lower yield strength, washers are required under both the head and the nut of the A490 bolt. This ensures that the load is distributed evenly and prevents the bolt from damaging the material.

- Oversized or slotted holes: In cases where you’re dealing with oversized, short-slotted, or long-slotted holes, washers are needed to provide proper bearing and prevent the bolt from slipping or loosening over time.

- Direct bearing on soft or thin materials: If the material you’re connecting is thin or soft (think thin plates or soft steel), washers are used to prevent the bolt head or nut from embedding into the material, which could lead to failure.

- Slip-critical or fully pretensioned joints: In joints that require slip-critical or pretensioning forces, using a washer ensures that the torque applied to the bolt during installation is reliable and maintains the required clamping force.

In short, when you’re working with A490 bolts, washers are usually required, and for good reason—they protect the integrity of your connections.

Key Differences Between A325 and A490 Bolts

A325 and A490 bolts are both commonly used in structural applications, but they differ in terms of strength, material, and cost. Let’s look at how they stack up:

| Item | A325 (F3125 Grade A325) | A490 (F3125 Grade A490) |

|---|---|---|

| Strength Level | Minimum tensile ≈ 120 ksi, yield ≈ 92 ksi | Minimum tensile ≈ 150 ksi, yield ≈ 130 ksi |

| Material | Medium carbon steel or weathering steel | Higher-carbon alloy or weathering steel |

| Hardness | 24–35 HRC | 33–39 HRC |

| Corrosion Protection | Can be hot-dip galvanized; commonly used outdoors | Cannot be hot-dip galvanized due to embrittlement risk |

| Typical Use | General structural steel connections | Heavily loaded connections, bridges, or special structures |

So, A490 bolts are significantly stronger than A325 bolts, making them suitable for more demanding applications. However, A490 bolts require more care in installation, including the use of hardened washers and special coatings, as they are more sensitive to hydrogen embrittlement during galvanizing.

Can A325 Bolts Be Fully Threaded?

Yes, A325 bolts can be fully threaded, but only in certain situations. Standard A325 bolts are partially threaded, with an unthreaded shank to prevent the threads from being in the shear plane of the connection. This helps maintain the strength and integrity of the joint. However, in certain cases, you may need fully threaded A325 bolts, such as for short bolts where the full length of the bolt is threaded or where the design calls for it.

If you decide to go with fully threaded A325 bolts, keep in mind that this can reduce the shear capacity compared to using bolts with an unthreaded shank. Always check with the engineer to ensure that using fully threaded bolts is acceptable for the specific design.

Specifications for ASTM F436 Washers

When working with structural bolts like A325 and A490, it’s crucial to choose the right type of washer to ensure that the joint remains secure. ASTM F436 washers are specifically designed for this purpose and come in different types, including flat, beveled, and extra-thick structural washers. These washers are hardened steel and are made to withstand high pretension loads without deforming.

Here are the key specs to keep in mind for ASTM F436 washers:

- Hardness: F436 washers are through-hardened or carburized to around Rockwell C 38–45.

- Dimensions: The washers come in various sizes, with a typical round washer ranging from 1/4 in. to 4 in. nominal bolt size.

- Material: You’ll find washers made from carbon steel or weathering steel for outdoor applications.

Frequently Asked Questions

Q1: Can I mix A325 and A490 bolts in the same connection?

It’s generally not recommended. A325 and A490 bolts have different strengths and elongation properties, which can lead to uneven load distribution. It’s best to use bolts of the same grade for each connection.

Q2: Which washer grade should I use with A325 or A490?

For both A325 and A490 bolts, you should use ASTM F436 hardened washers unless the project specifies otherwise.

Q3: Why can’t A490 bolts be hot-dip galvanized?

A490 bolts are susceptible to hydrogen embrittlement during hot-dip galvanizing, which can cause brittle failure. That’s why ASTM prohibits hot-dip galvanizing for these bolts.

Q4: Are F436 washers compatible with galvanized A325 bolts?

Yes, F436 washers can be supplied hot-dip galvanized and are commonly used with galvanized A325 bolts in outdoor applications.

Contact Hengrui Fastener for Custom A325 and A490 Bolts

In the world of structural bolts, washers play a vital role in ensuring your connections are strong and reliable. For A490 bolts, washers are often mandatory to ensure proper load distribution and prevent issues like local deformation. Always make sure to follow engineering guidelines and project specifications when choosing washers, and remember that F436 washers are generally the go-to choice for both A325 and A490 bolts.

For specialized applications that require custom solutions, Hengrui Fastener offers high-quality, customizable bolts and fasteners. Whether you need a specific size, material, or finish, Hengrui can provide tailored fasteners to meet your exact requirements. Contact Hengrui Fastener to learn more about our products and services.