Choosing the right fastener type is essential for any project. Using the wrong fit—metric or standard—can lead to costly delays, weakened structures, and unnecessary frustration. At Hengrui, we guide our clients daily on making the best choice for their needs. Understanding these differences will help ensure your project’s success from the start.

Key Differences Between Metric and Standard FastenersIn short, Metric fasteners, measured in millimeters, are widely used worldwide and preferred in global manufacturing. They have coarse or fine threads defined by pitch. Standard (imperial) fasteners, measured in inches, are primarily used in the U.S. and feature thread types like UNC or UNF, measured in threads per inch.

Key Differences Between Metric and Standard Fasteners

Three main aspects set these fasteners apart: thread pitch, diameter, and markings.

Thread Type

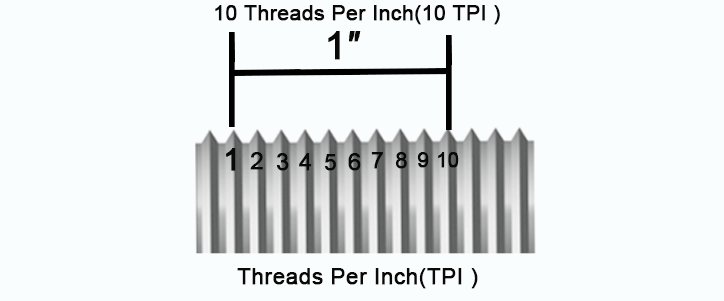

Metric threads are categorized by pitch—the distance between threads. For example, an M10 x 1.5 metric bolt has a 10mm diameter and 1.5mm pitch. Standard threads, however, use TPI (threads per inch), so a 1/4″-20 bolt has 20 threads per inch. This is where incompatibility issues arise, as thread pitch and TPI are not interchangeable between systems.

Diameter and Length

Metric fasteners use whole millimeter measurements, like M6 or M8. Standard fasteners, however, use fractional inch sizes, such as 1/4” or 1/2″. This difference requires attention during assembly, as mismatches can cause alignment and fitting problems.

Markings

Metric fasteners typically have strength ratings stamped on the head, such as 8.8 or 10.9, indicating tensile strength. Standard fasteners use head markings like lines or grades (e.g., Grade 5 or Grade 8) to signify strength.

Standards Organizations for Fasteners

Standards ensure fastener quality, durability, and compatibility. Here’s a look at the top organizations that set these crucial standards:

- ASTM International

ASTM, once called the American Society for Testing and Materials, creates widely recognized global standards. For example, ASTM A193 sets requirements for alloy-steel bolts used in high temperatures. These standards help ensure safety and reliability across many industries. - SAE International

SAE standards, commonly used in the automotive and aerospace fields, set specific requirements for fasteners. For example, SAE J429 defines bolt grades, while J995 provides guidelines for nuts in these high-precision industries. - ANSI (American National Standards Institute)

ANSI sets and approves standards across different industries, ensuring they meet both national and international requirements. Many of these standards directly impact fastener quality throughout North America. - ASME (American Society of Mechanical Engineers)

ASME provides tolerances and specifications for mechanical devices, including fasteners. Its standards are essential for maintaining tight tolerances in engineering applications. - IFI (Industrial Fasteners Institute) Representing North American fastener manufacturers, IFI doesn’t create new standards but manages existing ones and publishes technical information to assist producers.

- ISO (International Organization for Standardization)

Known for ISO 9001 and similar quality standards, ISO’s guidelines ensure global consistency and quality, aiding international trade. For fasteners, ISO 9001 is particularly valuable for ensuring production quality. - DIN (German Institute for Standardization)

DIN standards, especially for metric fasteners, are highly regarded in Europe and ensure seamless integration across borders.

How to Ensure Correct Fastener Selection for Your Project?

Choosing the correct fastener type is essential to avoid compatibility issues and ensure project success. Here are a few strategies for selecting the right fastener:

Confirm Measurements

Check whether specifications are metric or standard. Mixing these can lead to poorly fitting parts, causing stress points or instability.

Consult with Your Supplier

Contact reliable suppliers like Hengrui. With our expertise, we’ll help you choose the right fasteners for your project’s specific needs, whether metric or standard.

Use Conversion Tools Carefully

If you need to switch between metric and standard, use conversion charts or tools to check compatibility. Even if diameters match, thread pitch can differ greatly. Exact matches are essential to keep structures strong and secure.

By following these steps, you’ll reduce costly errors, avoid compatibility issues, and enhance the performance of your assemblies.

Conclusion

Knowing the difference between metric and standard fasteners is key to choosing the right parts for any project. At Shanghai Hengrui, we offer high-quality fasteners in both types, so you can get exactly what you need for precise and reliable results. For assistance with your order, contact us at +86-21-34201269 or visit our website for more information.