The difference between nuts and bolts may seem small, but it’s fundamental in many applications. Each plays a specific role in creating secure connections. Let’s explore their distinct functions to help you make the right choice for your next project.

A bolt has external threads and a head, used to fasten parts together by passing through a hole. A nut has internal threads, screwed onto the bolt to secure it. Nuts and bolts work together, with nuts tightening onto bolts to create a strong connection.

Let’s dive deeper into this topic.

What are Nuts?

Let’s start with the nut. A nut is typically hexagonal, which makes it easier to grip with a wrench. It has internal threads and is designed to mate with the external threads of a bolt or screw. The nut’s job is to hold everything securely by tightening onto the bolt, creating a strong, reliable connection.

Nuts come in all shapes and sizes. They can be used in construction, machinery, automotive industries, and many other applications. When you’re looking for a nut to fit a bolt, you need to ensure the threads match—otherwise, they won’t lock together properly. This alignment is critical in providing the secure connection you’re after.

What are Bolts?

Now, let’s talk bolts. A bolt is a cylindrical fastener with external threads and typically comes with a head that allows for tightening. It passes through a hole in the parts you want to join and is secured with a nut. The design of the bolt provides the strength necessary to hold materials together, making it ideal for structural work.

Bolts come in various shapes, sizes, and thread types. Some are partially threaded, while others are fully threaded, depending on the application. They are a staple in any project requiring two or more components to be securely fastened.

Types of Nuts and Bolts

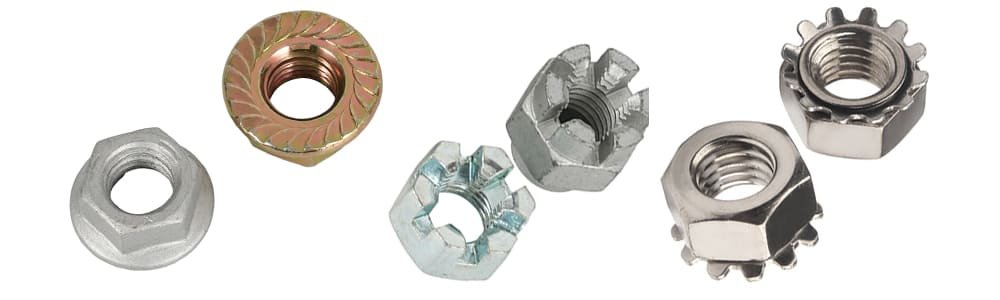

Types of Nuts:

Hex Nut

A hex nut is the most common type of nut you’ll encounter. Its six-sided design makes it easy to grip with a wrench, which is why it’s a staple in the construction and manufacturing industries. The hex nut is versatile and used in countless applications where strong fastening is required.

Lock Nut

The lock nut takes the standard hex nut to the next level by preventing loosening. It often comes with a nylon insert or serrated edges that grip the threads of the bolt, making it perfect for situations where vibrations could otherwise cause the connection to loosen. Lock nuts are ideal for automotive or machinery applications.

Acorn Nut (Cap Nut)

Ever wonder what covers the end of a bolt to give it a smooth, finished look? That’s where the acorn nut, or cap nut, comes in. It has a rounded top that not only adds a polished appearance but also protects the exposed end of the bolt from damage.

Coupling Nut

A coupling nut is long and cylindrical, designed to connect two male-threaded components. This type of nut is commonly used when you need to extend the length of a bolt or threaded rod. It’s a simple solution for lengthening fasteners while maintaining a strong connection.

Wing Nut

If you’re working on a project that requires frequent adjustments, a wing nut is your best friend. This nut has two large “wings” that allow you to easily tighten or loosen it by hand—no tools required. Wing nuts are often found in furniture assembly or other applications where quick changes are needed.

Jam Nut

A jam nut is much thinner than a standard nut and is typically used in combination with another nut. Its role? To secure the primary nut in place, preventing it from loosening. This is essential in situations where the bolt or stud might be subject to movement or vibrations.

Serrated Flange Nut

The serrated flange nut has an extra feature—a built-in flange with serrated edges. These edges grip the surface underneath, making it difficult for the nut to come loose, especially in vibration-heavy environments like automotive or heavy machinery.

Square Nut

Looking for something a bit more robust? The square nut has four sides and usually offers a larger surface area than its hexagonal counterparts. This extra grip makes it ideal for heavy-duty applications where a stronger fastening is needed.

Nylon Insert Lock Nut

For extra security in environments prone to vibrations, the nylon insert lock nut is a must-have. The nylon insert grips the bolt’s threads, preventing the nut from coming loose. It’s commonly used in automotive and machinery applications where durability is a priority.

Types of Bolts:

Hex Bolt

A Hex Bolt is a widely used fastener featuring a hexagonal head. The cylindrical body can be fully or partially threaded, depending on the application. This multi-purpose bolt is commonly seen in construction, machinery, and various industrial settings. The hexagonal head allows for easy gripping and tightening with a wrench.

Carriage Bolt

Carriage Bolts are easily recognizable due to their rounded head and square neck. The square neck prevents rotation when secured into place, making them ideal for applications where movement must be avoided.

They’re most commonly used in woodworking projects, furniture assembly, and decking, offering a clean and smooth finish with the head remaining exposed.

Lag Bolt

Known for its large diameter and coarse threads, a Lag Bolt is perfect for heavy-duty applications, especially when fastening large timber or heavy materials.

The head of the lag bolt is typically larger, allowing for more torque when driven into wood or other materials. These bolts are a staple in wooden structures like decks, wooden beams, and framing.

Flange Bolt

Flange Bolts come equipped with a built-in flange under the head, which acts like a washer, distributing the load over a larger surface area. This feature is particularly beneficial in metal-to-metal applications where pressure needs to be spread evenly to prevent wear.

Socket Head Cap Screw

The Socket Head Cap Screw features a cylindrical head with a hexagonal socket, allowing it to be tightened or loosened with an Allen key or hex wrench. This bolt type is perfect for applications where space is limited, as the head takes up minimal room while still providing ample torque.

Eye Bolt

An Eye Bolt is designed with a looped head, often used to attach ropes, chains, or cables. Its application is prevalent in lifting and rigging operations, where secure attachment points are required. Eye bolts are commonly found in construction, marine, and rigging industries.

Anchor Bolt

The Anchor Bolt is designed to secure structures to concrete foundations. Typically larger than other bolts, it can have either threads or a specialized anchor head to ensure a solid connection. Anchor bolts are vital in large-scale construction projects, such as securing buildings, bridges, or machinery to concrete bases.

Plow Bolt

Plow Bolts feature a flat head with a square neck, similar to carriage bolts, but designed for heavy-duty wear resistance. These bolts are commonly used in agricultural equipment and heavy machinery, where bolts are subjected to extreme conditions and wear over time.

J-Bolt

A J-Bolt is aptly named for its J-shaped body, with threads at one end for securing components. These bolts are often used to anchor structures into concrete or fasten objects in place. Common applications include foundations, concrete forms, and support systems.

Double-End Bolt (Stud Bolt)

The Double-End Bolt, also known as a Stud Bolt, features threads on both ends and a smooth center section. It is commonly used in piping systems and machinery where two components need to be fastened together with nuts on either end.

Shoulder Bolt

A Shoulder Bolt features a smooth shoulder between the head and the threaded section, allowing parts to rotate or move around the bolt. These are commonly used in machinery, pivot points, and moving parts where rotational motion is required.

Common Nut and Bolt Materials

Choosing the right material for your nuts and bolts can make or break your project—literally. Here are some common materials:

- Carbon Steel: Strong, affordable, and versatile. They’re commonly used in construction and automotive projects due to their reliability and cost-effectiveness.

- Alloy Steel: Combines carbon steel with alloying elements like chromium, molybdenum, nickel, and vanadium to improve strength, hardness, and corrosion resistance.

- Stainless Steel: Offers good corrosion resistance due to the presence of chromium, making it suitable for applications with moisture or corrosive conditions.

- Stainless Steel: Stainless steel fasteners are resistant to rust and corrosion, making them ideal for outdoor or marine applications.

- Brass: This material resists corrosion and offers good electrical conductivity. You’ll often see brass in electrical or plumbing applications.

- Aluminum: Lightweight but strong, aluminum is perfect for applications where reducing weight is key, like in aerospace.

- Titanium: Titanium is strong, lightweight, and resists rust, making it perfect for tough jobs like aerospace and military uses. It’s also safe for the human body, which is why it’s used in medical devices.

- Copper: Copper is known for its excellent electrical conductivity and resistance to rust. This makes it a great choice for use in electrical systems and areas with high moisture, like humid environments.

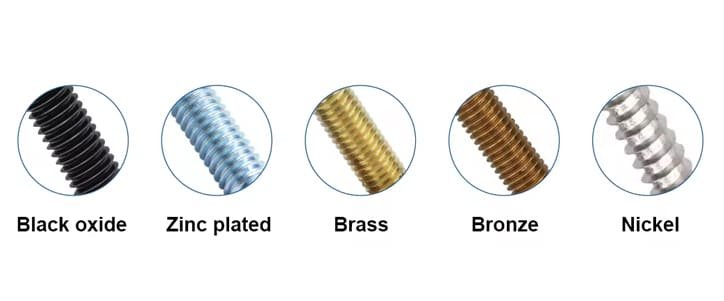

Common Nut and Bolt Coatings

The right coating can significantly extend the life of your fasteners. Here are a few common options:

Plain/Self Color: Fasteners without any coating, typically with an oil residue from manufacturing. These are best for indoor applications with minimal exposure to moisture.

Zinc Plating: Offers corrosion resistance with finishes in clear, blue, yellow, or black. It’s a versatile option for outdoor and automotive uses.

Black Oxide: A sleek, black finish that provides some corrosion resistance while looking sharp. Often used in automotive and firearms industries.

Hot Dip Galvanized (H.D.G): Fasteners are dipped in molten zinc, creating a thick, durable coating that’s perfect for coastal or harsh environments.

Chrome Plating: This provides a shiny, aesthetic finish with corrosion resistance, though it’s more costly than zinc plating. Chrome is often used when appearance is just as important as performance.

The right coating can significantly improve the lifespan of your fasteners, especially in environments exposed to moisture or chemicals.

Conclusion

Nuts and bolts are essential in a wide range of industries, from construction to automotive to aerospace. Understanding the differences between them, as well as the types available, materials used, and coatings, will help you choose the right fasteners for your projects. Whether you’re securing metal, wood, or other materials, making the correct selection can ensure safety, strength, and longevity.

If you have any questions or need help selecting the custom fasteners for your next project, feel free to reach out to us at Hengrui Fasteners. We specialize in both standard and custom fasteners and are here to support your business needs.