Ever wondered about the differences between anchor bolts and regular bolts? You’re not alone. In my role at Shanghai Hengrui Industry Co., Ltd., I’ve often been asked to clarify these distinctions. Let’s dive in and explore these fascinating fasteners!

**Anchor bolts and regular bolts serve different purposes and are designed accordingly. Anchor bolts are specifically engineered to secure structures to concrete, while regular bolts are versatile fasteners used to join components together across various industries. Anchor bolts feature designs that allow them to be embedded in concrete, offering maximum stability, whereas regular bolts are installed through pre-drilled holes and secured with nuts.

Anchor bolts are critical in construction for securing heavy equipment, structural elements, and other fixtures to concrete foundations or walls. Their design typically includes a threaded end for nut attachment and a head or hook that embeds into the concrete, ensuring strong anchorage.

To keep you engaged, let’s get into the specifics.

What is an Anchor Bolt?

An anchor bolt is a type of fastener designed to attach objects or structures to concrete. It features a threaded end for nut attachment and a head or hook that embeds into concrete. Anchor bolts are essential for securing heavy equipment, structural elements, and other fixtures to concrete foundations or walls.

What are the different types of anchor bolts?

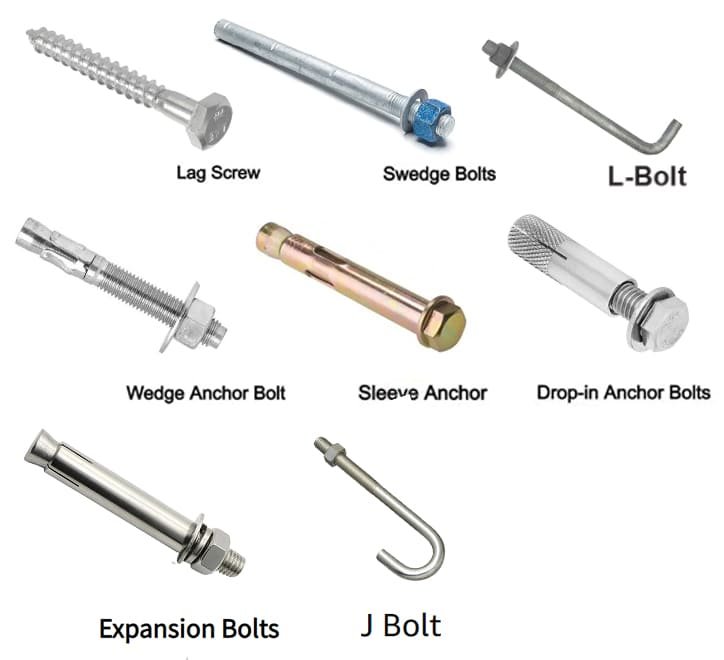

Anchor bolts come in various shapes and sizes, each serving a specific purpose. The most common types include:

- Cast-in-place anchor bolts: These are set into concrete during the pouring process. They typically have a J-shape or L-shape at the embedded end.

- Wedge anchor bolts: Post-installed anchors that expand when tightened, creating a wedging effect against the sides of the drilled hole.

- Sleeve anchor bolts: Similar to wedge anchors but with a sleeve that expands as the bolt is tightened.

- Adhesive anchor bolts: Use a chemical adhesive to bond the bolt to the concrete, suitable for high load capacities.

- Expansion anchor bolts: Expand as they are tightened, creating pressure against the sides of the hole for a secure hold.

- Drop-in anchor bolts: Pre-expanded anchors inserted into a hole and set with a special setting tool.

- Screw anchor bolts: Have helical threads that cut into the concrete as they are installed, providing a mechanical bond.

What is the Strongest Anchor Bolt?

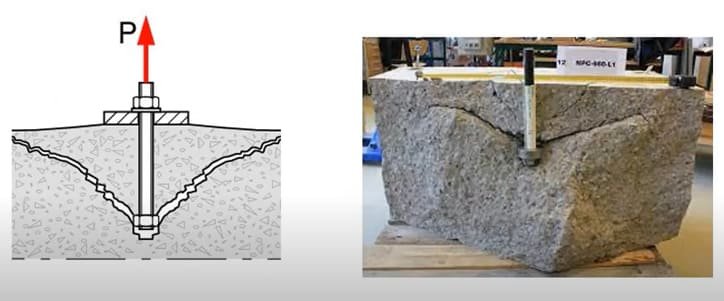

Determining the strongest anchor bolt depends on various factors, including material composition, size, embedment depth, concrete strength, and installation method. Anchor bolts made from high-strength steel alloys and installed correctly can withstand significant loads.

The strength of an anchor bolt is influenced by:

- Material: High-strength steel alloys are typically used for anchor bolts requiring high load capacities.

- Size: Larger diameter anchor bolts generally have higher load capacities.

- Embedment Depth: Deeper embedment into concrete enhances the anchor bolt’s pull-out resistance.

- Concrete Strength: The quality and strength of the concrete substrate affect the overall strength of the anchor system.

- Type of Anchor: Different types of anchors offer varying strength characteristics based on their design and installation method.

For critical applications requiring high load capacities, such as in structural engineering and heavy machinery installations, consulting with a structural engineer is recommended to determine the most suitable anchor bolt type and size.

How to choose an anchor bolt?

When choosing an anchor bolt, consider load requirements, environmental conditions, and specific applications. Understanding project demands and selecting the appropriate type and grade of anchor bolt will ensure the structure’s safety and stability. Selecting the right bolt for your project can feel like trying to choose the best ice cream flavor—there are just so many options! But here’s a simple guide to help:

- Consider the Load: Heavy loads require anchor bolts with higher load capacities, especially when anchoring to concrete.

- Environmental Conditions: Assess the exposure to elements such as moisture, temperature variations, and corrosive substances.

- Specific Application: Choose an anchor bolt that matches the material and configuration of the objects being anchored (metal to metal, concrete to concrete, etc.).

What Grade is a Standard Anchor Bolt?

Anchor bolts are available in different grades, each indicating the bolt’s strength and performance characteristics. The most common grades include:

- Grade 2: Low strength, suitable for light-duty applications.

- Grade 5: Medium strength, used in general construction and moderate load-bearing applications.

- Grade 8: High strength, reserved for heavy-duty applications requiring maximum load-bearing capacity.

The grade of an anchor bolt is determined by its material composition, heat treatment, and performance under specified testing conditions. Selecting the appropriate grade ensures the anchor bolt meets the required performance standards for the specific application.

For many general construction applications, Grade 2 or Grade 5 anchor bolts are commonly used.Grade 8 anchor bolts are typically reserved for heavy-duty applications or where higher strength is required.

What is the Most Common Anchor Bolt?

The most common anchor bolts vary depending on the industry, application, and regional construction practices. Wedge anchors and expansion anchors are widely used due to their versatility, ease of installation, and ability to provide a secure hold in various concrete and masonry applications.

For general construction purposes, wedge anchors and expansion anchors are preferred for their reliability and adaptability to different installation conditions.

Conclusion

In summary, anchor bolts are specialized fasteners designed for securing objects to concrete, offering robust anchorage and load-bearing capacity. Regular bolts, in contrast, are versatile fasteners used for joining components together in various industries. Understanding the differences between anchor bolts and regular bolts helps in selecting the right fastener for specific construction and engineering applications.

Explore more about anchor bolts and other fastening solutions at Hengrui Industry Co., Ltd. For inquiries or custom fastening solutions, contact us.