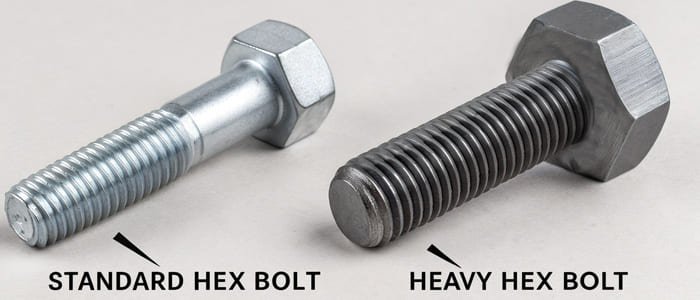

When it comes to fastening solutions, selecting the right type of bolt can make all the difference. If you’re choosing between a hex bolt and a heavy hex bolt, understanding their differences in terms of strength, size, and application is crucial. Let’s explore these key differences and find out which one is ideal for your project.

Hex bolts and heavy hex bolts differ primarily in their head size and strength. Heavy hex bolts have larger, thicker hexagonal heads, offering greater load distribution and enhanced bearing capacity. They are stronger, typically exceeding 600 MPa in tensile strength compared to standard hex bolts, which usually offer around 400 MPa. These bolts are designed for heavy-duty applications like bridge construction, steel fabrication, and other structural projects where strength and durability are critical.

Now that we’ve covered the basics, let’s dive deeper into the differences in terms of their dimensions, strength, and specific uses.

Hex Bolts: Characteristics and Uses

1. Standard Head Size

Hex bolts are easily identifiable by their hexagonal (six-sided) heads. They are designed to be driven with a wrench, making them one of the most commonly used fasteners. Their head size is relatively smaller compared to heavy hex bolts. This standard size works perfectly in applications where extreme load-bearing isn’t required.

2. Versatility and Material Options

Hex bolts come in various sizes and materials like steel, stainless steel, and alloy steel. This flexibility makes them suitable for a wide range of applications, including general construction, mechanical assembly, and automotive repairs. Whether you’re tightening something in your home workshop or assembling mechanical equipment, hex bolts are reliable.

3. Common Applications

Hex bolts are incredibly versatile and can be used in various general applications. From automotive repairs to furniture assembly, they are commonly used for medium-load projects. Due to their compact head size, they are easier to work with in confined spaces, and their availability in multiple materials allows flexibility for different environmental conditions.

Common uses include:

- Construction: As fasteners for structural components that don’t face excessive load.

- Mechanical Equipment: For attaching parts in machinery where high strength is not the primary concern.

- Automotive: For parts that require basic load-bearing capabilities, such as engine components or suspension systems.

Heavy Hex Bolts: Characteristics and Uses

1. Larger, Thicker Head for Enhanced Strength

Heavy hex bolts feature larger, thicker heads compared to standard hex bolts. This provides better clamping force and a larger bearing surface, making them ideal for high-load applications. These bolts are designed to handle stresses that would deform a standard hex bolt, which is why they are favored for heavy-duty construction projects.

2. High Strength and Durability

The design of heavy hex bolts allows them to withstand higher tensile strengths, often exceeding 600 MPa. This strength is essential for high-stress applications such as bridge construction, steel fabrication, and offshore platforms, where the risk of corrosion and heavy mechanical load is present. These bolts can endure extreme environments, ensuring safety and stability in critical structures.

3. Strict Manufacturing Standards

Heavy hex bolts are manufactured according to more stringent industrial standards like ASTM A325 and ASTM A490, ensuring high levels of corrosion resistance and thermal stability. These properties make heavy hex bolts the go-to choice for environments requiring reliable performance under extreme conditions.

4. Heavy Hex Bolts – Critical for Heavy-Duty Applications

Heavy hex bolts are built for extreme conditions. They are used primarily in heavy-duty applications that require high strength and resistance to extreme environments. Due to their thicker head and higher tensile strength, they are perfect for industries such as bridge construction, steel fabrication, and offshore oil rigs.

Some key applications include:

- Infrastructure: Used extensively in bridge building, highway projects, and large steel structures.

- Offshore & Oil and Gas: Heavy hex bolts are frequently used in offshore platforms and petrochemical plants, where corrosion resistance is paramount.

- Industrial Equipment: Used in manufacturing heavy machinery and power plants, where mechanical reliability is critical under high stress.

How Should Hex and Heavy Hex Bolts Be Installed and Maintained?

1. Installation of Hex Bolts

Installing hex bolts is straightforward. Torque specifications are critical to ensure they are fastened securely without damaging the materials. Since hex bolts are designed for a wide range of general applications, they are easy to install using standard wrenches or impact drivers. Always ensure that the correct thread size and material compatibility are selected to avoid failure.

2. Installation of Heavy Hex Bolts

The installation of heavy hex bolts, on the other hand, requires more attention to detail due to their larger size and higher strength. Torque requirements are much higher for heavy hex bolts to ensure proper clamping force. When using these bolts in structural applications, proper installation practices such as using torque wrenches and lubrication are important to achieve the necessary preload.

3. Maintenance Considerations

Both hex and heavy hex bolts require periodic inspections to check for corrosion, loose threads, or head deformation. Heavy hex bolts, being used in harsher environments, may need more frequent inspections for corrosion and other forms of wear and tear. In coastal or marine environments, anti-corrosion coatings or stainless steel options might be necessary to extend the lifespan of both types of bolts.

What Are the Cost Considerations for Hex and Heavy Hex Bolts?

1. Cost of Hex Bolts

Hex bolts are typically more affordable than heavy hex bolts due to their smaller size and less demanding manufacturing standards. For standard construction projects or automotive repairs, they offer a cost-effective solution that still delivers adequate strength.

However, the cost can increase based on the material used (e.g., stainless steel or high-strength alloys), especially if the bolts need to be corrosion-resistant. The price may also vary depending on the size and quantity purchased, but in general, hex bolts are a budget-friendly option for most general projects.

2. Cost of Heavy Hex Bolts

Heavy hex bolts tend to be more expensive due to their larger size, thicker heads, and higher tensile strength. The materials used to manufacture heavy hex bolts, such as high-strength steel or alloy materials, can also drive up the price. For heavy-duty applications like bridge construction or offshore drilling, the cost of heavy hex bolts is justified by their superior strength and performance under extreme conditions.

While they might be more expensive upfront, investing in high-quality heavy hex bolts ensures safety and long-term durability, particularly in demanding environments. When considering bulk purchases or wholesale pricing, distributors often offer competitive rates.

FAQ

- What is the tensile strength of a heavy hex bolt?

- Answer: Heavy hex bolts typically have tensile strengths upwards of 600 MPa, significantly stronger than standard hex bolts, which are usually rated at about 400 MPa.

- Can standard hex bolts be used in heavy-duty applications?

- Answer: While standard hex bolts are effective for general construction and mechanical work, heavy hex bolts are preferred for high-stress environments due to their enhanced strength and performance.

- What are the dimensional differences between hex bolts and heavy hex bolts?

- Answer: Heavy hex bolts are larger in diameter and have a thicker head compared to standard hex bolts. For example, an M16 heavy hex bolt has a head width of 27 mm, while the standard version is only 24 mm.

- What standards and specifications apply to hex and heavy hex bolts?

- Answer: Hex bolts are generally made according to ISO 4014 or DIN 931 standards, while heavy hex bolts are manufactured to more stringent standards like ASTM A325 and A490, which require higher tensile strength, corrosion resistance, and thermal stability.

Conclusion

In conclusion, while both hex bolts and heavy hex bolts serve vital roles in fastening solutions, heavy hex bolts stand out in terms of strength, load-bearing capacity, and suitability for high-demand applications. Hex bolts, while reliable, are more suitable for general use, whereas heavy hex bolts are the go-to choice for structural projects where strength and durability are non-negotiable.

Contact Hengrui Fastener for Custom Fastener

For specialized applications that require custom solutions, Hengrui Fastener offers high-quality, customizable bolt and fasteners. Whether you need a specific size, material, or finish, Hengrui can provide tailored fasteners to meet your exact requirements. Contact Hengrui Fastener to learn more about our products and services.