Ever wonder what all those parts of a bolt actually do? If you’re dealing with fasteners, you’ve probably seen bolts in all shapes and sizes. But do you know the names of all the critical parts? Let’s break down the anatomy of a bolt so you can sound like a pro next time you’re ordering or discussing bolts for your project.

Bolts are essential fasteners in countless industries, and they’re designed for a specific function. Understanding the parts of a bolt is important for anyone who works with mechanical systems, from the automotive industry to construction. Let’s dive into the structure of a bolt.

Bolt Head

The head of a bolt is the topmost part. It’s the one that you grip with your tool to tighten or loosen the bolt. It’s designed to be strong enough to withstand the force of a wrench or screwdriver. There are several common types of bolt heads, each suited for different types of tools and applications.

- Hex Head: This is the most common bolt head. It has six sides, and you can easily grip it with a wrench. It’s versatile, simple, and works in most situations.

- Socket Cap: A socket cap bolt has a cylindrical head with a recess in the center. To tighten or loosen it, you’ll need an Allen wrench, which fits into the recess. These are often used where there’s limited space for a wrench.

- Slotted Head: This is a flat, single-slot head designed to be turned with a flat-head screwdriver. It’s simple, but not as secure as other head types, especially when dealing with high torque.

Each bolt head is designed with a specific tool in mind. The purpose? To make sure the right tool grips the bolt securely, allowing for proper installation or removal.

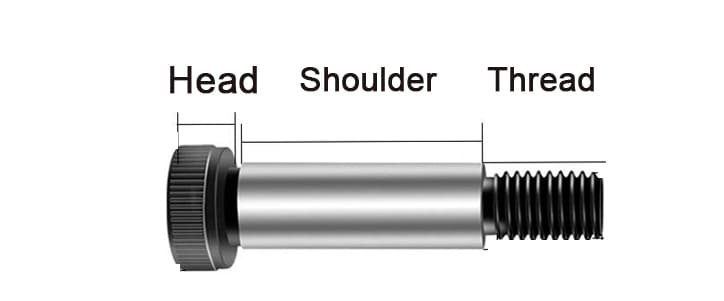

What is the Smooth Part of a Bolt Called?

Now, let’s talk about the smooth part of the bolt—the shank. The shank is the smooth, cylindrical section of the bolt between the head and the threaded portion. It doesn’t have any threads and is typically used to align the bolt in place before threading into a nut or tapped hole.

The shank is important because it ensures the bolt stays in place and doesn’t wobble during installation. The length of the shank can vary, depending on the bolt’s design and intended use.

In some applications, bolts with a longer shank are used when the bolt needs to pass through thick materials before threading into the nut. For example, bolts used in structural applications often have long shanks to provide a solid, secure hold.

What Are the Ridges on the Bolt?

The ridges on a bolt are the threads, which are the helical grooves that spiral around the shaft of the bolt. The purpose of these threads is to allow the bolt to screw into a nut or tapped hole. This is the part that makes a bolt work—without threads, you wouldn’t be able to tighten the bolt, and it wouldn’t hold anything together.

The threading works by creating a mechanical grip between the bolt and the material it’s being fastened to. When the bolt is turned, the threads engage with corresponding threads in a nut or tapped hole, pulling the materials together tightly.

The shape, depth, and design of the threads can vary depending on the bolt type and its specific function. For example, finer threads are often used for precision fastening, while coarse threads are preferred for heavy-duty applications where greater strength is needed.

Bolt Anatomy Breakdown

To better understand how a bolt works, let’s break down the anatomy of a bolt:

- Bolt Head: The part you grip with your tool to tighten or loosen the bolt.

- Shank: The smooth, unthreaded section that helps align the bolt.

- Threads: The ridges or spirals on the bolt that allow it to screw into place and hold materials together.

Each of these components plays a critical role in ensuring that the bolt can be used effectively for its intended purpose. Whether you’re working in the automotive, mechanical, or construction industry, understanding bolt anatomy is essential for ensuring the right fastener is used for each application.

Why Does the Thread Matter?

Threads on a bolt are key to its functionality. They create the friction and mechanical advantage that allows the bolt to secure materials. A bolt with improperly designed threads may fail under pressure or not provide a tight enough hold.

Thread types include:

- Unified Thread Standard (UTS): Common in North America.

- Metric Threads: Used in Europe and other parts of the world.

- Acme Threads: Designed for power transmission applications.

Depending on the type of material you’re fastening, choosing the right thread is crucial. For example, fine threads are better for softer materials, while coarse threads are better suited for thicker materials that need to bear heavy loads.

Bolt Parts You Need to Know

While the head, shank, and threads are the primary parts of a bolt, there are other elements that contribute to its function and performance. These include:

- Tip: The tip of the bolt is pointed or flat, depending on the design. It’s often used to help guide the bolt into place.

- Neck: The neck of a bolt is the portion that is just below the head. It may have some design features like a smooth surface, which is helpful for certain applications.

- Shoulder: Some bolts have a shoulder, which is an unthreaded section that helps to provide spacing and ensure proper alignment with components.

The combination of these bolt parts contributes to the overall strength and performance of the fastener. Depending on your application, different parts of the bolt will be more or less important.

Conclusion

So there you have it. The parts of a bolt—head, shank, and threads—each serve a specific function, and understanding them helps you make the right choices when it comes to fasteners. Whether you’re in construction, manufacturing, or even energy, the right bolt can make all the difference.

Understanding the anatomy of bolts helps ensure you’re selecting the right fastener for your needs. Remember, the right bolt with the right parts can make a world of difference in your project’s success!