Do you ever think about the little things that hold the world together? I’m talking about washers. These little guys are often overlooked, but they play a big role in keeping things stable and lasting a long time. Let’s talk about washers.

Washers are used to distribute the load of threaded fasteners (such as a screw or bolt) over a larger surface area. This prevents the fastener from digging into the material and causing damage, which is particularly important when fastening softer materials like wood or aluminum. They absorb vibrations and provide sealing to prevent liquid ingress. They ensure fasteners remain tight and stable, protecting materials and preventing corrosion.

Want to know more? Stick around as we go through the different types of washers, what they’re used for, and why they’re so important in the fastener world.

What is a Washer?

A washer is a common mechanical component, typically round and made from metal or plastic. It’s a little bit bigger in diameter than the hole in the middle. Washers are used with screws or bolts to help them work better.

The primary function of washers is to distribute the load, reduce friction, and prevent loosening, ensuring the fastener remains tight and stable over time.

Washers come in all different shapes, sizes, and materials, each designed to do a specific job. Let’s talk about the different types of washers and what they’re used for.

Types of Washers

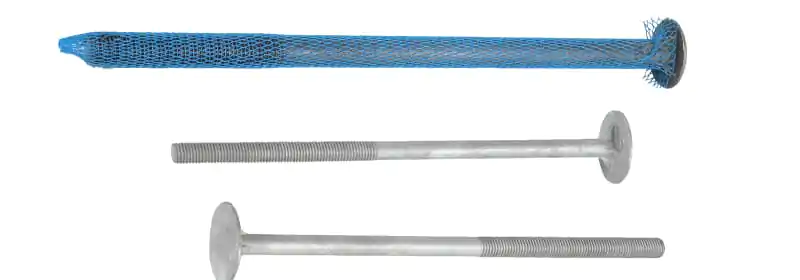

Flat Washers

Flat washers are thin, circular metal or plastic discs with a central hole. They are used to distribute the load and reduce friction in general mechanical connections. The uniform thickness and flat surface help to stabilize the fastener and enhance its durability.

Flat washers are versatile and widely used in engineering and everyday applications.

Spring Washers

Spring washers are circular metal discs cut into a spiral shape, giving them elasticity. Typically made from stainless steel or carbon steel, they prevent loosening through their elasticity and friction. Carbon steel spring washers are also known as iron washers.

Spring washers are ideal for connections subject to frequent assembly and disassembly, such as motor mounts, to prevent loosening due to vibration.

However, in critical connections relying on friction to transfer power, spring washers may reduce joint rigidity and should be used with caution.

Tooth Lock Washers

Tooth lock washers feature serrated edges that dig into the material, increasing friction and preventing loosening. Available in internal and external tooth designs, they are used in applications where extra locking force is needed.

Tooth lock washers are particularly useful in automotive industries for securing components.

While they provide strong locking capabilities, they may damage softer materials and lose effectiveness with repeated use.

Tab Washers

Tab washers have tabs or notches that bend to lock in place around bolts or nuts, offering resistance in harsh environments with extreme heat or vibration.

They are excellent for securing fasteners in heavy-duty applications.

Fender Washers

Fender washers have a larger outer diameter, spreading weight over a broader area to increase stability and weight distribution.

Great for when you need to greater load distribution.

Where should the washer be placed?

Washers are typically placed between the head of a bolt or screw and the material being fastened, or between the nut and the material. Here are the key points on where washers should be placed:

Between the Bolt Head and the Material

- Load Distribution: Placing a washer here helps distribute the clamping force over a larger area, preventing the bolt head from damaging the material.

- Friction Reduction: Acts as a buffer, reducing friction during tightening and minimizing surface damage.

- Surface Protection: Protects the material from corrosion and wear, especially when dissimilar metals are involved.

Between the Nut and the Material

- Load Distribution: Ensures even distribution of the clamping load, preventing distortion or damage to the material.

- Friction Reduction: Reduces friction between the nut and the material for smoother tightening.

- Surface Protection: Creates a barrier to prevent galvanic corrosion when different metals are used.

With Locking Washers

- Placement: Lock washers, such as split lock washers, should be placed between the flat washer and the nut or bolt head. This provides additional security against loosening due to vibration or thermal cycling.

In summary, washers are generally placed under the bolt head or nut to distribute load, reduce friction, and protect surfaces. Lock washers are used in conjunction with flat washers to prevent loosening in high-vibration environments.

When to Use a Washer?

Washers should be used in various situations to ensure the integrity and longevity of the fastener connection:

- Soft Materials: When fastening soft materials like wood or plastic to prevent damage.

- Load Distribution: To distribute the load and prevent the fastener from embedding into the material.

- Vibration Absorption: Use spring washers in vibrating equipment like motor mounts to absorb vibrations and prevent loosening.

- Waterproofing: In fasteners requiring waterproofing to provide a seal against liquid ingress.

- Spacing and Fitment: To adjust the spacing and fitment of fasteners.

- Corrosion Prevention: To prevent galvanic corrosion between dissimilar metals.

- Uneven Surfaces: When connecting uneven surfaces.

When Not to Use a Washer?

Washers might not be necessary in certain situations:

- Uniform Materials: When fastening uniform materials where surface damage isn’t a concern.

- Large Bearing Surfaces: When the fastener has a large bearing surface.

- Precision Metal Connections: In precision metal-to-metal connections, such as some automotive engine parts.

- Space Constraints: When space limitations prevent washer use.

The decision to use washers should be based on the specific needs of the application, considering material, environmental conditions, and joint requirements.

How to Use Washers Correctly?

- Match Washer and Screw Sizes: Ensure the washer size matches the screw for proper fit and to prevent potential issues.

- Proper Placement: Place the washer under the screw head or nut to maximize its effect, distributing pressure evenly and preventing material damage.

- Even Tightening: Tighten screws gradually and evenly to avoid over-tightening, which can damage or deform the washer.

- Use Appropriate Tools: Use torque wrenches or other suitable tools to achieve optimal tightening, avoiding over-tightening or thread damage.

Following these steps ensures the effective use of washers in screw connections, enhancing stability and durability.

Conclusion

Washers, though often overlooked, are vital components in fastening systems. They distribute loads, reduce friction, prevent loosening, and protect surfaces, ensuring the stability and longevity of connections. Understanding the types of washers and their correct usage can significantly improve the performance and reliability of mechanical assemblies.

That’s it! Now you know all about washers and their importance in our world. If you have any more questions or need high-quality washers for your projects, You can contact me via email at info@hrfastener.com or visit our website at Hengrui for more information.