What is a Well Nut?

A well nut, also known as rubber nut, rawl nut or expanding nut, is a removable rivet nut fastener, It consists of a flanged EPDM neoprene bushing and a threaded brass or steel insert.

When a bolt or screw is tightened into the brass insert, the neoprene bushing end compresses and expands, securing the nut to the surface material and providing a strong, vibration-resistant and waterproof seal.

Rubber well nut is a nut commonly used for fastening and sealing in the automotive and aerospace industries.

What is the difference between Well nut vs Rivnut?

Well nuts and Rivnuts (also called rivet nuts or threaded inserts) are both used to provide threaded inserts in materials, but their functions and ways of use are very different:

Advantages of Well Nuts:

- Vibration Dampening: The rubber material isolates and dampens vibrations, making them excellent for sensitive equipment prone to vibration.

- Water and Air Seal: Due to their rubber construction, neoprene well nuts provide a watertight and airtight seal around the bolt, which is beneficial in marine, automotive, and outdoor applications.

- Easy Installation and Removal: Well nuts are easy to install and remove. Rubber nuts do not require specialized tools; a simple screwdriver or a wrench is sufficient. This is advantageous for maintenance or temporary installations.

- Non-Conductive: The rubber material provides insulation, which can be helpful in electrical installations.

- Material protection: Wellnuts made of flexible material prevent damage to fragile or soft surfaces during fastening, which makes them suitable for use in plastics, glass or ceramics.

- Corrosion Resistance: The brass insert and rubber body are resistant to corrosion, making wellnut suitable for harsh environments.

- Reusability: Well nuts can be removed and reused without damaging the material they were fastened into.

Comparison to Rivnuts:

Rivnuts are usually made from metal and are designed for permanent installation. They provide strong and durable metal thread in materials such as sheet metal and are ideal for high-strength applications. The rivet nut requires an installation tool, which deforms the nut to grip the body material, creating a strong, wear-resistant thread. Compared to well nuts, they are stronger but less flexible.

Are Well Nuts waterproof? Are Well Nuts strong? Are Well Nuts reusable?

This is one of the most asked questions about well nuts and the answer is YES, The well nut is waterproof and utilizes its rubber body to seal against moisture when installed correctly. They provide medium strength suitable for light to medium loads but are not suitable for heavy-duty applications. Although they are reusable, their effectiveness may be reduced with each use due to material wear.

What are rubber well nuts used for?

Rubber well nuts are widely used in many fields, especially in industries that require anti-vibration, sealing or waterproofing requirements. The following are some typical application scenarios:

- Water transportation:

- Rubber well nuts are used to fasten and seal fittings on boats, kayaks, and other watercraft.

- Ideal for installing accessories that need to be protected from leaks.

- Automotive Industry:

- Rubber well nuts are fasteners used for vehicle panels, lights and other components.

- Vibration resistance is particularly useful for protectingsensitive parts.

- Electronics product:

- Install circuit boards or other electronic components that require vibration isolation.

- Provides safe and insulated fastening points in electrical enclosures.

- Aerospace Industry:

- Used in aircraft interior structures to absorb vibration and provide a waterproof and airtight seal.

- Suitable for fixing sensitive equipment to reduce vibration damage during flight..

- Furniture and Home Improvement:

- In furniture manufacturing, used to secure lightweight accessories and decorative pieces such as handles and hooks.

- Suitable for installations where shock absorption or damage to fragile materials is required.

- Outdoor and architectural applications:

- Well nuts are used in fixed installations on outdoor equipment and signage.

- Provides some flexibility and reduces damage caused by weather changes..\

- Medical equipment:

- Used in the assembly of medical devices, especially those that require shock absorption or avoidance of direct metal-to-metal contact.

Because Well nuts are easy to install and protect materials well, they are particularly popular in scenarios that require quick assembly and disassembly or frequent maintenance. However, if shockproofing and sealing against water are not very much needed, Rivnuts, self-tapping screws can be used as alternatives.

How to use Wellnut?

How do you install Wellnut?

Installing Wellnuts is relatively simple and is suitable for a wide range of materials and applications. The following are detailed installation procedures:

Drilling: First, drill a hole in the mounting surface that matches the outer diameter of the rubber nuts. Make sure the hole size is appropriate for the rubber nuts size selected.

Insert the Well Nut: Insert the Well Nut into the pre-drilled hole. Make sure the rubber part is fully inside the hole and the flange is tight against the surface.

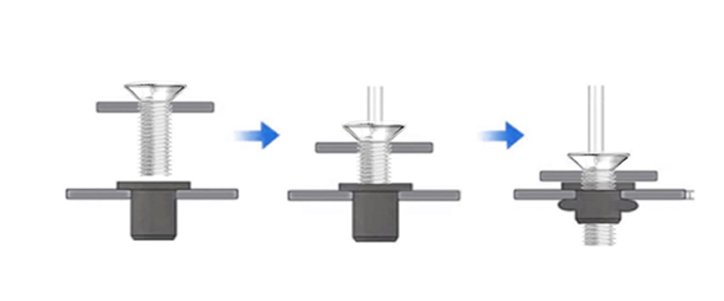

Install Screws or bolts: Insert appropriately sized screws or bolt through the internal threads in the center of the Well Nut.

Tighten the screws: Use a screwdriver or wrench to tighten the screws. As the screw is tightened, the rubber portion of the Well Nut will begin to expand, tightly gripping the inside wall of the hole. Tighten until the rubber expands significantly and is securely seated in the hole.

Check the fixation: Make sure the Well Nut is securely installed and not wobbly or loose. Proper tightening will prevent damage to the rubber and ensure a good seal and hold.

How do you remove a Wellnut?

Well Nut is designed to be easily removed for repair or replacement. The removal process is as follows:

Loosen the screw: Using a screwdriver or appropriate wrench, turn the screw secured in the Well Nut counterclockwise until it is completely loosened.

Remove the screws: When the screw is completely loosened, it from the Well Nuts.

Pulling out the Well Nut: Since the rubber part of the wellnut has expanded when tightened, it may require slight force to pull it out of the hole. Use pliers to gently grasp the flange portion of the rubber well nut and pull it out.

If you are interested in incorporating well nuts into your project or need a similar type of fastener, please feel free to contact Hengrui for more information. We specialize in supplying a wide range of high quality bolts and nuts.