We’ve all been there, staring at a pile of fasteners, wondering which one is the right choice. The confusion between bolts and screws is common, even among professionals. Let me help you clear that up.

The most obvious way to differentiate between a bolt and a screw is by their threading. Bolts typically have a partially unthreaded shank and require a nut for fastening, whereas screws are threaded fully along their shaft and can be driven directly into materials. Bolts are used with pre-drilled holes and a nut, tightened by turning the nut, while screws often create their own holes as they are driven in, tightened by turning the head.

So, let’s dive deeper and explore difference between a screw and a bolt

What is a Bolt?

A bolt is a type of mechanical fastener with a cylindrical shaft that has external threads. Bolts are typically used to hold together two or more objects by inserting them into pre-drilled holes and securing them with a nut.

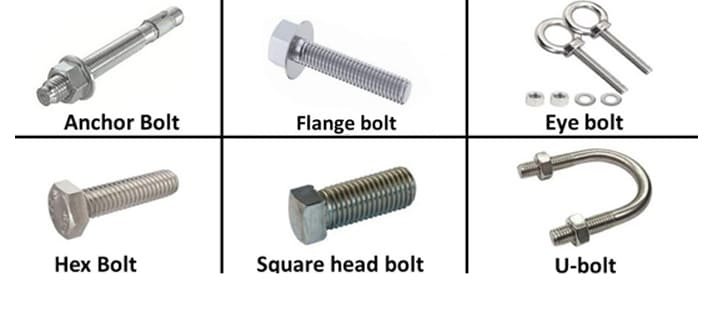

Different Types of Bolts

- Hex Bolts: These bolts have a hexagonal head and are commonly used in construction and machinery. They provide excellent grip and torque transmission.

- Flange Bolts: With a flange or a wide surface under the head, these bolts distribute pressure and reduce the risk of loosening. They’re often used in automotive and mechanical applications.

- Square Head Bolts: Featuring a square head, these bolts offer better torque transmission and are used in older constructions and restoration projects.

- U-Bolts: Shaped like the letter “U,” these bolts are used to secure pipes or round objects.

- J-Bolts: With a “J” shape, these bolts are often used as anchors in concrete foundations.

Common Bolt Materials

- Carbon Steel: The most common material, suitable for general purposes.

- Stainless Steel: Known for excellent corrosion resistance, ideal for outdoor and wet environments.

- Alloy Steel: High strength, used for demanding applications.

- Brass: Good corrosion resistance and electrical conductivity, often used in electrical and decorative applications.

- Aluminum: Lightweight and corrosion-resistant, perfect for aerospace and light structures.

What is a Screw?

A screw is a fastener with a helical ridge, or thread, wrapped around a cylinder. Unlike bolts, screws usually do not require nuts and can be driven directly into materials.

Different Types and Uses of Screws

- Self-Drilling Screws: These have a drill bit end, allowing them to drill and tap their own hole in metal or other hard materials. Common in metal roofing and sheet metal work.

- Self-Tapping Screws: These screws can create their own threads in materials such as metal, plastic, or wood. They are used in situations where a secure hold is necessary, such as in electrical enclosures and metal frameworks.

- Drywall Screws: Specifically designed for fastening drywall to wood or metal studs. They have a bugle head to prevent tearing the drywall.

- Chipboard Screws: These screws are used for fastening particle board and other composite materials. They have deep threads to provide a strong grip.

- Wood Screws: These screws are used for connecting pieces of wood. They have a sharp point and deep threads to ensure a strong hold in wood.

- Machine Screws: Used for fastening metal parts together, often with a pre-tapped hole or with a nut. They come in various head shapes, including flat, round, and hex.

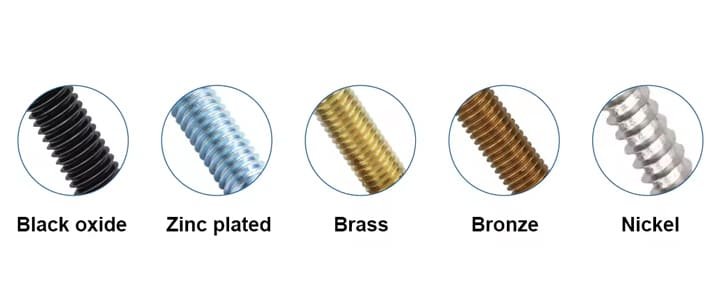

Characteristics of bolt vs. screw Materials

- Carbon Steel: Most common material for general-purpose screws, providing good strength and affordability.

- Stainless Steel: Offers excellent corrosion resistance, suitable for outdoor and marine applications.

- Brass: Decorative, non-magnetic, and corrosion-resistant, often used in electrical applications.

- Aluminum: Lightweight and resistant to corrosion, ideal for aerospace applications.

- Titanium: Known for a high strength-to-weight ratio, commonly used in high-performance and aerospace applications.

- Nylon: Non-conductive and lightweight, often used in electronic applications.

- Zinc-Plated Steel: Provides some corrosion resistance, commonly used in household applications.

- Galvanized Steel: Offers better corrosion resistance than zinc-plated, used in outdoor and marine environments.

- Copper: Used in electrical applications for its excellent conductivity.

- Alloy Steel: High strength, used in demanding applications where extra durability is needed.

What is a Screw with No Point Called?

A screw with no point is typically called a set screw. These screws are designed to secure one object within another without the need for a head protruding out. Set screws are essential in applications where a flush or hidden fastener is required.

Key Characteristics of Set Screws

- Design: Set screws have no head and machine threads for use in a tapped hole. They do not have a point or tip at the end.

- Purpose: They are used to prevent movement or rotation of a component, often by pressing against a flat or dimpled surface.

- Common Types:

- Cup Point: Has a cup-shaped end to indent into the contact material.

- Cone Point: Has a sharp, penetrating point for wedging into the material.

- Half Dog Point: Features a cylindrical tip fitting into a drilled hole.

- Knurled Cup Point: Has a serrated ridge to resist loosening due to vibration.

- Drive Style: Typically feature an Allen (hex socket) drive, but other drive styles are also available.

- Applications: Used in machinery, tools, and mechanical devices to secure components in place.

- Material: Available in various materials, including stainless steel and alloy steel.

What is the Difference Between Tapping and Non-Tapping Screws?

Tapping screws, also known as self-tapping screws, have threads that allow them to cut into the material, creating their own thread. They often have a pointed tip and can be driven directly into materials like metal, plastic, or wood without the need for a pre-drilled hole.

Tapping Screws

- Design: Sharp, cutting threads and often a pointed tip.

- Function: Create their own threads as they are driven into the material.

- Installation: Often don’t require pre-drilled holes, or only need pilot holes.

- Applications: Common in sheet metal work, plastic assemblies, and some woodworking applications.

- Advantages: Faster installation and reduced need for separate tapping operations.

Non-Tapping Screws

- Design: Standard threads and may have various tip designs.

- Function: Require pre-existing threads or pre-tapped holes to function properly.

- Installation: Typically require pre-drilled and tapped holes.

- Applications: Used in machinery, furniture assembly, and general construction.

- Advantages: More precise fit when used with properly prepared holes.

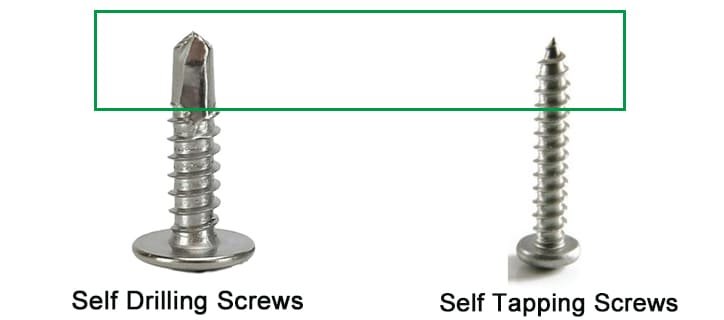

Difference Between Self-Drilling Screws and Self-Tapping Screws

While self-drilling screws and self-tapping screws might seem similar, they have distinct differences.

Self-Drilling Screws

- Design: Have a drill bit end that allows them to drill and tap their own hole.

- Use: Suitable for metal and other hard materials.

- Efficiency: Fast installation as they do not require a pre-drilled hole.

- Applications: Used in metal roofing, steel framing, and other fast installations.

Self-Tapping Screws

- Design: Have sharp threads but no drill bit end.

- Use: Usually require a pilot hole to be pre-drilled.

- Flexibility: Can be used in a variety of materials, including metal, plastic, and wood.

- Applications: Suitable for electronics, metalworking, and woodworking.

Conclusion

In the end, knowing the differences between bolts and screws, the different kinds of both, and where and how to use them makes a big difference. Whether you’re putting the roof on a house or assembling some do-it-yourself shelves, using the right screw or screwing item makes a big difference in how long whatever you’re building will last.

That’s it! If you have more questions or need any fasteners, feel free to contact us at Shanghai Hengrui Industry Co., Ltd. We’re always here to help you with your fastening needs.