Are you looking for a reliable way to secure objects to concrete? Many find this task challenging, but there’s a solution that works—concrete screws. These screws provide a strong and secure hold, making them an excellent choice for both residential and commercial projects.

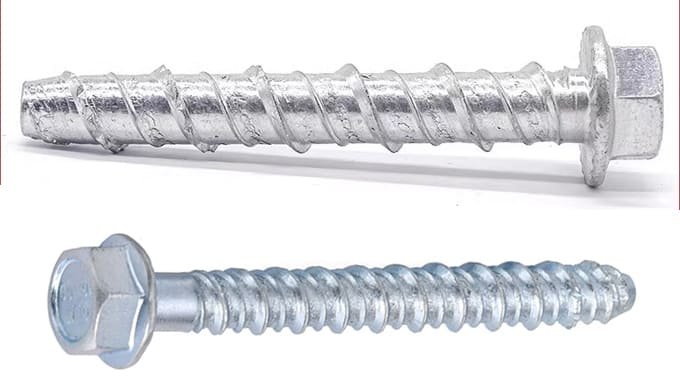

Galvanized concrete screws are highly effective for fastening in concrete and masonry. They offer excellent corrosion resistance, making them ideal for indoor and outdoor use, especially in moist environments. Their self-tapping design simplifies installation and provides a strong hold, especially in solid, non-loose materials. Perfect for various construction applications.

Now that we’ve established their effectiveness, let’s explore concrete screws in more detail. We will examine their key features and benefits, so by the end of this article, you’ll understand why galvanized concrete screws are an excellent choice for any job site.

What Are Concrete Screws?

Concrete screws, also called masonry screws, are made specifically for securing items to concrete, brick, or block walls. They are different from regular screws because they are made from hardened steel and have sharp, cutting threads.

These unique threads are designed to cut into concrete, providing a strong and reliable hold. As you drill, the design of these screws also helps clear away the dust, allowing them to go deeper and grip better.

Concrete screws are essential in construction projects because they offer a stable and secure solution. When you need a dependable option for securing items, concrete screws are the ideal choice.

The Materials and Coatings of Concrete Screws

The material and coating of concrete screws are very important for how well they perform, especially for galvanized screws.

Concrete screws are usually made from carbon steel concrete screws or stainless steel concrete screw. Carbon steel screws have a zinc coating, giving them a blue or silver look. This coating helps protect against rust, making them good for indoor use. Stainless steel screws are stronger and resist rust even better, making them perfect for outdoor use or in damp areas.

Galvanized screws have an extra layer of zinc coating, providing even better protection against rust than regular zinc coatings. This makes them a great choice for both indoor and outdoor projects. They can handle tough weather and last longer, ensuring strong and reliable performance.

What Are the Advantages of Galvanized Concrete Screws?

Galvanized concrete screws have many advantages that make them a top choice:

- Easy Installation: You don’t need extra fasteners or anchors. Just drill a pilot hole and screw them in. This saves time and effort.

- Versatility: They work well in both cracked and solid concrete, making them useful for different types of projects.

- Strong Grip: The saw-tooth threads create a tight hold, ensuring the screws stay firmly in place.

- Removable and Reusable: You can take these screws out and use them again without damaging the surrounding material. This makes them a sustainable option.

- Corrosion Resistance: The zinc coating or stainless steel provides long-lasting protection against rust, even in tough environments.

Common Uses of Concrete Screws

Concrete screws are versatile and used in various applications across construction projects:

- Attaching ventilation systems, pipes, and electrical installations.

- Fastening rails, cable trays, and steel structures.

- Installing fences, clamps, and supports.

- Mounting TV brackets and shelves.

- Securing handrails and railings.

- Anchoring outdoor structures like fences and pergolas.

These screws are a go-to choice for many construction professionals due to their reliability and ease of use.

How to Install Concrete Screws?

Installing concrete screws is easy if you follow these steps:

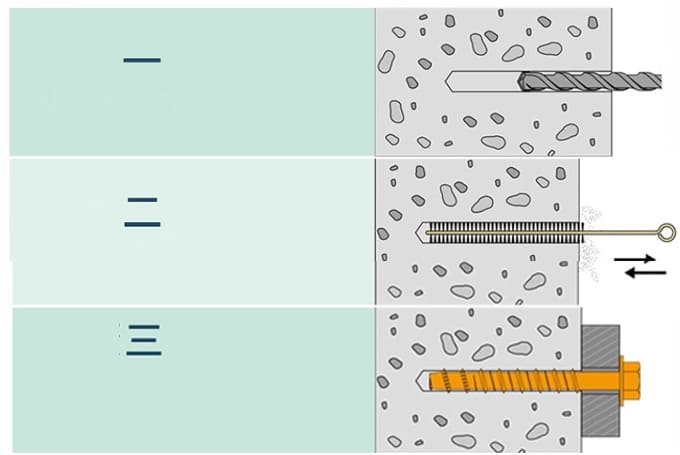

- Select the Right Drill Bit: Use a carbide-tipped masonry drill bit that’s a bit smaller than the screw. This helps the screw fit tightly.

- Drill the Pilot Hole: Drill a hole deeper than the screw length. This extra depth makes room for dust and debris.

- Clean the Hole: Use a vacuum or brush to clear out any dust and debris. This ensures the screw will hold securely.

- Insert the Screw: Put the screw into the pilot hole. Use a hammer drill or impact driver to drive it in. Apply steady pressure and turn it clockwise until it’s fully in place.

Troubleshooting Tips: If the screw is hard to turn, gently tap it with a hammer. If the screw spins without tightening, the hole might not be deep enough or could have debris inside. Make sure the hole is clean and deep enough for the screw.

How to Choose the Right Length of Concrete Screw?

Choosing the right length for a concrete screw is crucial for ensuring a secure installation. Here’s what you need to consider:

- Thickness of the Material: Measure the thickness of the material you’re fastening to determine the screw length.

- Embedment Depth: A minimum of 1 inch of screw embedment into the concrete is typically required for a secure hold. For softer materials, a deeper embedment of up to 1-3/4 inches might be necessary.

- Total Length Calculation: The total length of the screw should be the thickness of the material plus the desired embedment depth.

Is Pre-drilling Necessary for Concrete Screws?

Yes, pre-drilling is very important when using concrete screws. Concrete is a tough and dense material, so screws can’t cut their own threads easily. By pre-drilling, you prevent cracking and make sure the screw can go deep enough into the concrete for a strong hold. Pre-drilling also clears out dust, helping the screw fit tightly.

Where Are Concrete Screws Most Commonly Used in Construction?

Concrete screws are commonly used in:

- Prefabricated Buildings: For securing wall panels, staircases, and balconies.

- Curtain Wall Projects: To attach support structures to the main building.

- Pipeline Installations: Securely fixing electrical and plumbing pipes.

- Equipment Installation: Mounting outdoor units, solar panels, and more.

- Interior Renovations: Fixing drywall, partitions, and cabinetry to concrete.

Conclusion

Galvanized concrete screws are a reliable and efficient choice for a wide range of construction needs. Their durability, ease of use, and versatility make them an essential tool for professionals. Whether you’re working on an indoor or outdoor project, these screws ensure a secure and lasting hold.

For all your fastener needs, Please contact us to Hengrui. We’re here to help you get the job done right!