Have you ever struggled with screws that won’t stay secure, no matter how tightly you fasten them? This common issue can lead to frustration and even damage to your projects. However, the proper use of lock washers can effectively prevent screws from loosening, ensuring a stable and reliable connection. Let’s explore how to correctly use lock washers with screws to achieve the best results.

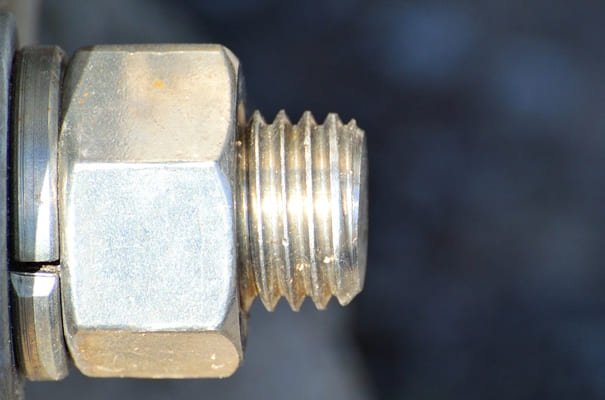

Place the lock washer directly under the screw head, ensuring its teeth or split ring engage with the screw. This setup helps secure the fastener by preventing loosening.

Now that you know the basics, let’s explore what lock washers are, their types, when to use them, and how to remove them if needed. Ready? Let’s get into the nitty-gritty.

How do lock washers work?

Lock washers are specialized washers designed to prevent nuts, bolts, and screws from loosening due to vibration or torque. They work by creating tension that secures the fastener in place. Think of them as tiny bodyguards for your fasteners, making sure everything stays tight and secure.

These washers are made from materials like stainless steel, aluminum, or bronze and feature a split, coiled, or toothed design that generates tension when compressed. By evenly distributing the load and preventing rotation, lock washers play a crucial role in maintaining the integrity of your assembly over time.

Types of Lock Washers

Not all lock washers are created equal. Depending on your application, you might need a specific type to get the job done right. Here are some of the most common types of lock washers:

- Split Lock Washers: These are the most commonly used type, also called spring washer, featuring a split ring that bites into the fastener when compressed. They’re great for general-purpose use.

- External Tooth Lock Washers: These have teeth on the outside that lock into the nut or bolt head, providing a strong grip. They’re often used where the appearance of the fastener is important, as they hide the teeth under the head of the screw.

- Internal Tooth Lock Washers: Similar to the external type, but with teeth on the inside, these washers grip the fastener near the head. They’re useful when space is limited or when you need a clean look on the outside of the assembly.

Each type has its own unique application, so choosing the right one can make a big difference in the performance of your assembly.

When and How to Use Lock Washers?

Lock washers should be used whenever there’s a risk of the fastener loosening due to vibration or dynamic loads. This is especially true in industries like automotive, aerospace, and heavy machinery, where the stakes are high, and the consequences of a loose fastener can be catastrophic.

To use a lock washer:

- Place it directly under the nut , screw or bolt head. The washer’s split or teeth should bite into the surfaces to prevent rotation.

- Tighten the fastener securely. Ensure that the washer is fully engaged and not loose. If the washer can move, it won’t perform its locking function effectively.

How to Remove a Locking Washer?

To remove a lock washer, simply pry it loose with a screwdriver after removing the nut or bolt. Once removed, discard the lock washer, as most are designed for single use. The teeth or split ring deform under pressure and won’t work effectively if reused.

Before installing new fasteners, clean the surface where the lock washer was placed to remove any debris or corrosion. Remember, lock washers are meant for one-time use.

Does the Spring Washer Go Above or Below the Flat Washer?

Here’s the typical lock washer placement: Screw Head, Lock Washer, Flat Washer (if used), Material Being Fastened, and Nut. The lock washer should be placed directly under the nut or the head of the screw.

In this setup, the flat washer, if included, helps distribute the load and protect the surface being fastened. This combination provides a strong locking mechanism, effectively preventing loosening due to vibration.

In this arrangement, the lock washer is placed directly under the nut or the head of the screw. The flat washer, if included, helps distribute the load and protect the surface being fastened. This setup provides a strong locking mechanism to prevent loosening due to vibration.

Conclusion

Lock washers are simple yet crucial components in any assembly where secure fastening is a must. By choosing the right type and ensuring proper installation, you can avoid the costly and potentially dangerous consequences of a loose fastener.

Whether you’re working in heavy industry or just assembling a DIY project, understanding how to use lock washers effectively will ensure your fasteners stay tight and secure。

Feel free to reach out to us at Shanghai Hengrui Industry Co., Ltd for any of your lock washers needs. We are here to help you find the perfect solution for your applications.